During 3D printing, materials are released into the atmosphere.

Where do they end up?

Neglecting your duties to control fumes can have serious consequences.

DON’T LEAVE IT TO CHANCE

Small scale models, larger prototypes or mass manufacturing – whatever 3D printing process you use, some form of contaminant is generated which can become airborne. They may be solid particles, gas or vapour.

The risks

Ultra-fine particles (UFP) in the nanoparticle size range (<100um) – too small to be seen but the dangers are real.

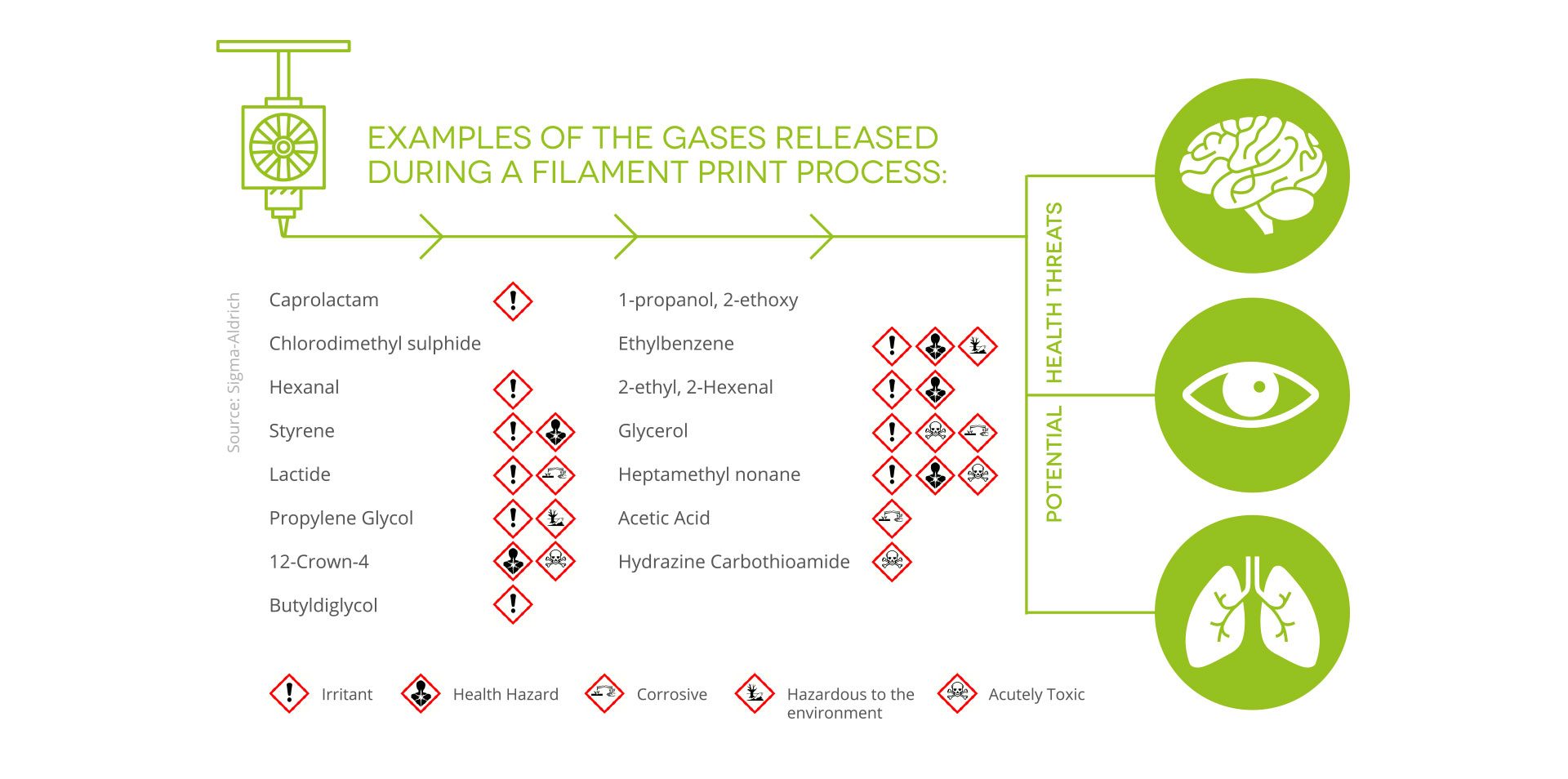

Volatile organic compounds (VOCs) – releasing unpleasant, toxic odours.

Airborne contaminants come in all shapes and sizes, but there are some that can be particularly harmful. The effect on health can range from headaches, eye irritation and skin problems to respiratory damage, occupational asthma, damage to the central nervous system and cancer.

Failure to take appropriate action to control these can have serious consequences.

A variety of consumable and equipment factors can influence emissions, including machine design and set-up, and operating temperatures, as well as additives, colourants and composition of materials used.

Whether you’re running 3D printers in a school or a large-scale factory, all airborne substances must be considered as potentially harmful:

To the users

Since 3D printing involves high temperatures, melting and sintering, it is likely that they emit a wide range of pollutants and emissions into the surrounding air. The effects caused by inhalation or reaction to the particulate can be long lasting and even life-threatening.

To the environment

Responsible manufacturing needs responsible practices. We all need to look after the world we live in.

Reducing or eliminating exposure is the best form of protection

Without proper filtration, even non-toxic ultrafine particles may cause oxidative stress, inflammatory mediator release, and could induce heart disease, and other systemic effects. A robust association has been observed between fine particulate levels and lung cancer, and cardiopulmonary disease.

3D printers should be operated with adequate ventilation or extraction

Don’t leave yourself exposed: understand the potential risks and extract them

How can BOFA help you?

Using effective fume extraction and filtration systems can help avoid the risk of costly health and safety litigation for the employer; maintains the reliability of the machine, and protects operators from potentially harmful fumes.

Our team of industry and application experts have developed systems specifically for the 3D printing sector.

Regardless of the size of process you are working with, BOFA has the system you need.