V 250

V 250

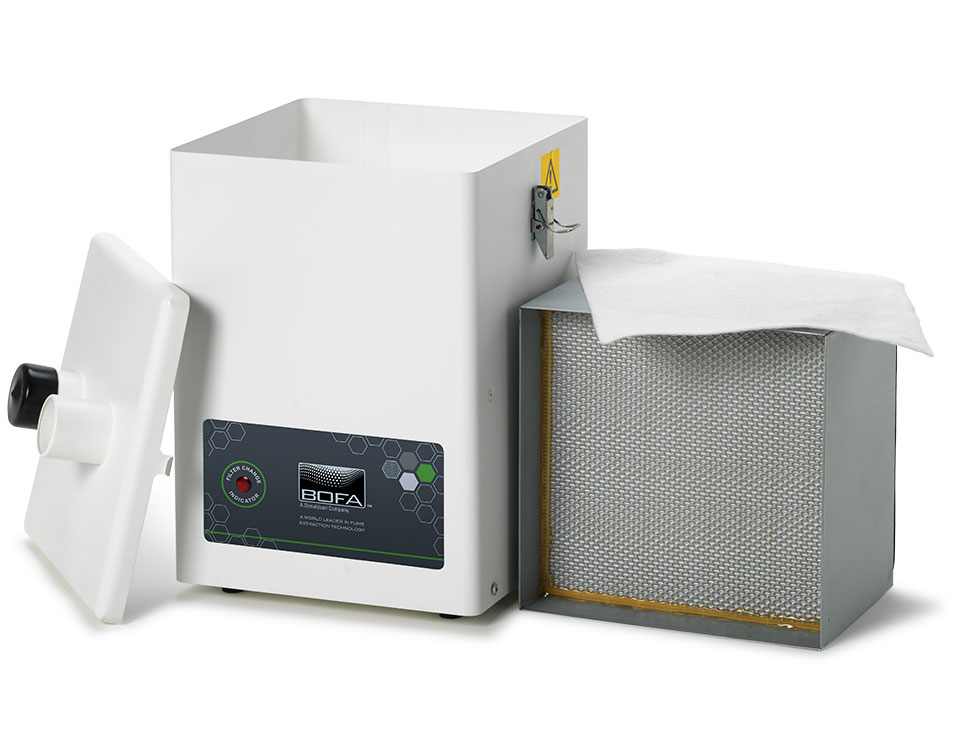

BOFA’s V 250 extraction unit has been designed to help capture fumes generated during hand soldering tasks. This portable system is offered in a number of configurations to cater for different factory layouts and contains everything required to set up two operators with ease.

Fast and easy installation allows this unit to be moved with the workbench when factory layouts need changing due to production demands. The unit’s low noise level and fully comprehensive filtration capabilities make it perfect for today’s electronics manufacturing environments.

See how the airflow of this unit works here.

View the product video here.

Were you looking for the DentalPRO Mono? We no longer make this product, but the V 250 system will meet your requirements.

Is this the system for you?

Let our knowledgeable team support you in choosing the most appropriate system for your requirements.

We offer a range of accessories for many of our units

Please refer to our accessories page for further information and then get in touch with our experts to define exactly what you need.

Key features of the V 250

HEPA filter

Advanced carbon filter (ACF) technology

ProTECT service plan

SureCHECK quality standard

Technical specification

Granulated carbon gas filter

Standard

Filter blocked indicator

Standard

99.995% HEPA filtration

Standard

Unique flip top flush sealing mounting plate

Optional

Remote speed control and power switch

Optional

2 x table mount installation kit and extraction arm

Optional

Wide selection of arms

Optional

Datasheet correct at time of publishing. For specific applications, please contact us for details.