Search your system below.

Find an extraction accessory that’s right for you

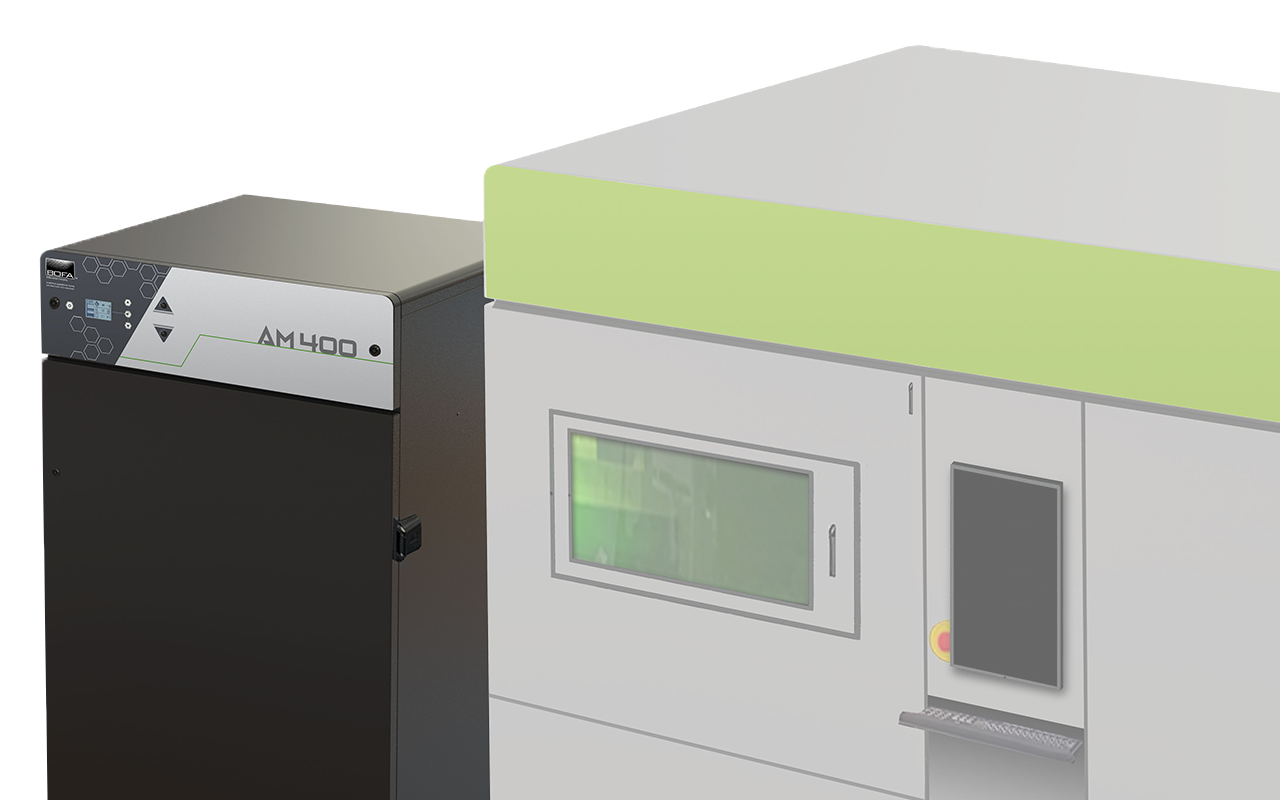

A world leader in fume and dust extraction systems

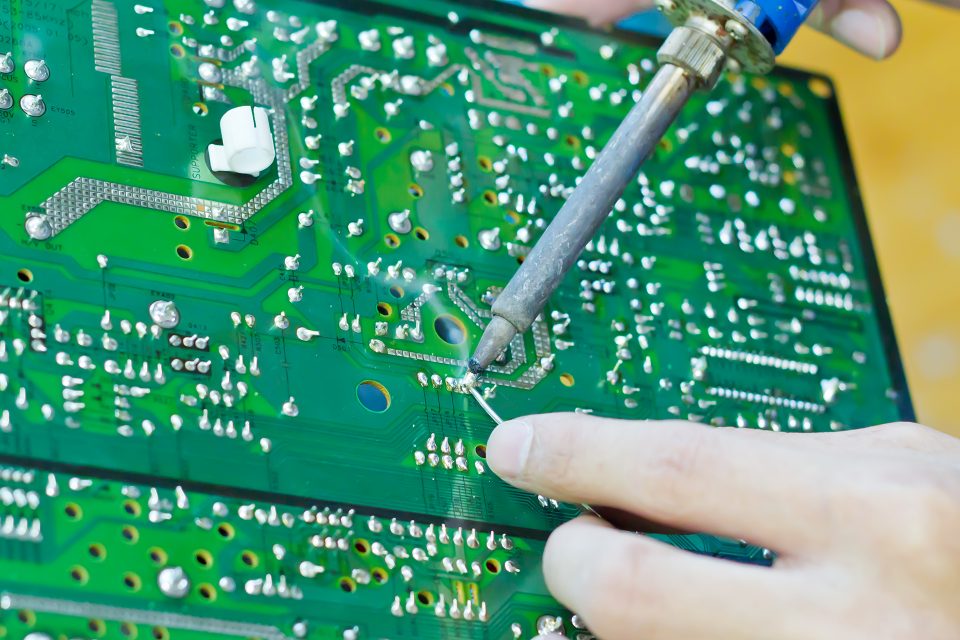

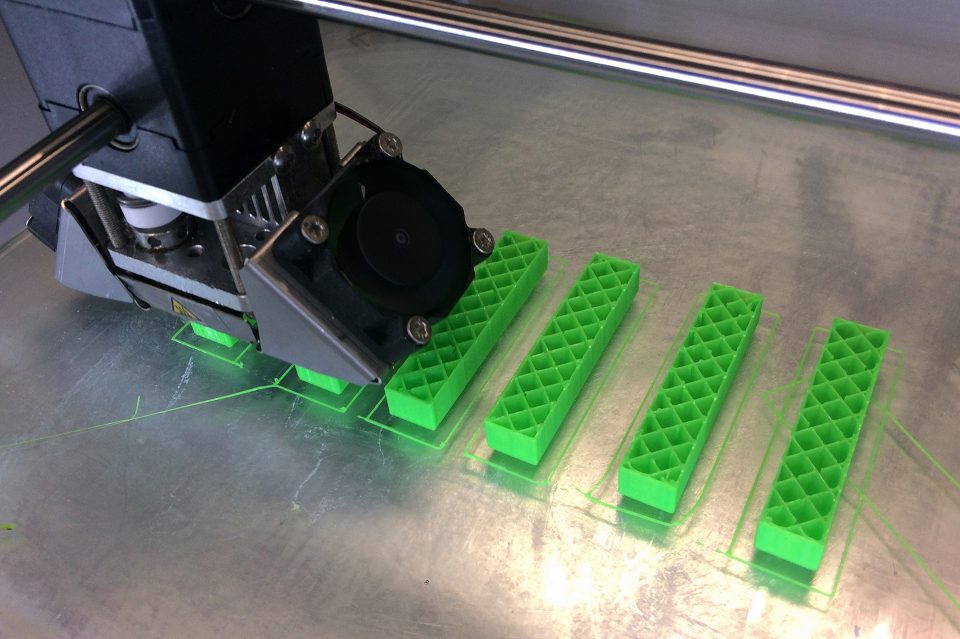

At BOFA, we design, develop and manufacture fume and dust extraction systems for a wide range of industrial sectors and applications. Our products play a very important part in the workplace environmental programmes of organisations across the world, while at the same time helping to improve industrial process performance by minimising disruption to production.

No compromise, just great, innovative technology.

Find fume and dust extraction systems specially designed for your industry

Be the first to receive BOFA updates

Sign up to receive industry information and news alerts covering fume and dust extraction technology, best practice and regulatory compliance.