There are three main areas of consideration associated with the fume.

Workplace environment management

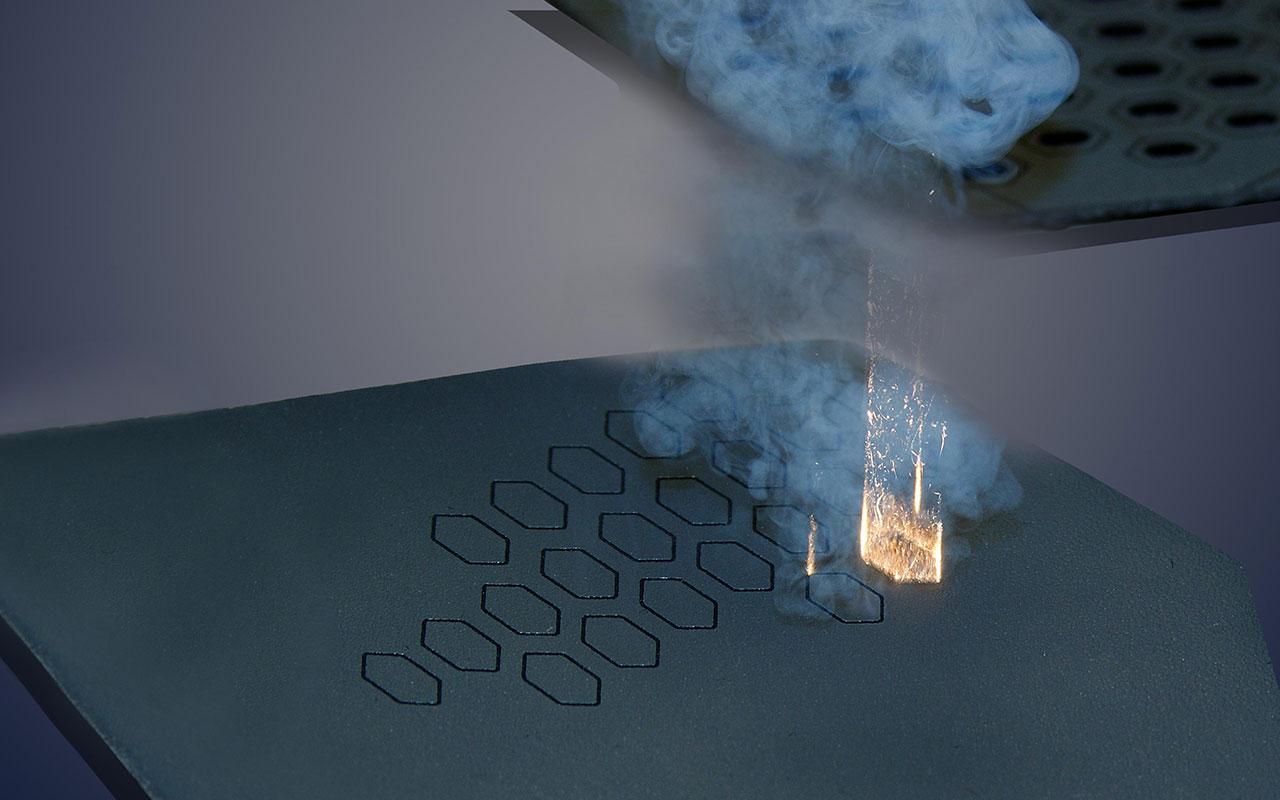

Filtering particulate is an important part of a workplace environment management plan (EHS plan)

Laser efficiency

The effects on the laser optics

Product contamination

The effects on the products being lasered

Workplace environment management

LGAC particles generally fall within the respirable range, so addressing filtration of those particulates is an important piece of your overall workplace environment and industrial hygiene program.

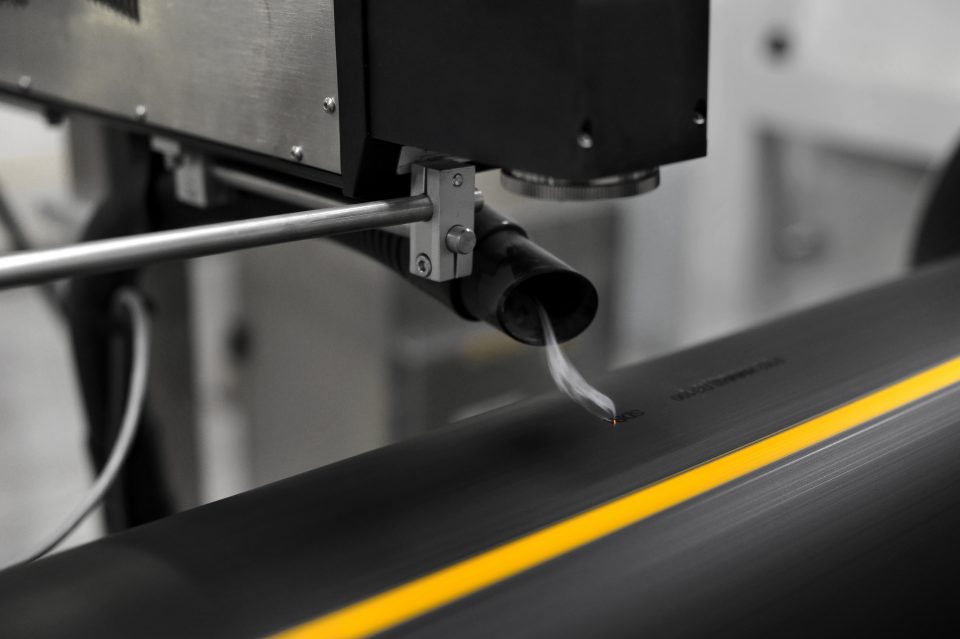

Laser efficiency

The optical system of the laser is susceptible to damage from particulate getting burnt onto the lens which reduces the laser efficiency and on marking applications can effect the quality of the code.

Additionally particulate in the laser beam can refract/reflect the light which diffuses the beam.

Product contamination

Marking applications on open containers are vulnerable to particulate settling in the container which contaminates the product being filled.