Many years of designing and manufacturing fume extraction and filtration systems for a variety of industries has given BOFA the experience and knowledge to work with you and help find the appropriate system for your process.

Our understanding of industrial processes and applications are reflected in the design and manufacturing procedures applied to our range of standard, inline and patented filters.

BOFA fume extractors can play a key role in your health and safety programme.

Pre-filters

The pre-filter is designed as a barrier, to help capture the larger dust and particulate, helping to protect the HEPA filter from premature blocking.

BOFA offer a range of pre-filters, all designed for different applications and processes, depending on the amount of dust being extracted.

The efficiency of the pre-filter is directly related to the life of the HEPA in that the more particulates captured in it, the less can pass through and prematurely block the HEPA. Most pre-filters have an efficiency grading of F5 - F7*.

*According to EN779.

HEPA filters (High-Efficiency Particulate Air)

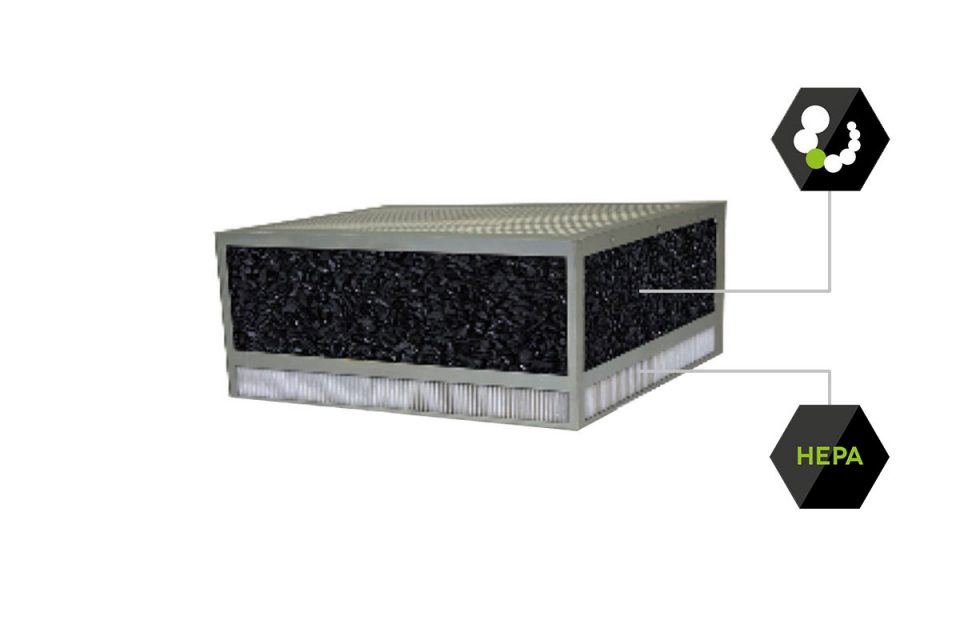

HEPA filters used by BOFA are of the mini pleat design. They are generally manufactured by specialist filter companies to help ensure that the latest manufacturing and test methods are adopted. Each filter incorporates a series of webbing between the pleats. This feature not only guarantees even spacing for full filter coverage between each pleat, but also alleviates the possibility of airflow vibration or collapse.

Filters should be individually tested and certified to a minimum efficiency of 99.995% down to 0.3 microns.

The BOFA ADVANTAGE micro filters are positioned within the system in such a way that the particulates are not only captured but held within the media.

This is not the case with conventional reverse airflow systems where particulate can fall away and rest on the outside of the pre-filter creating a potential health risk on filter replacement.

Mini pleats can be produced with depths of up to 200mm within each pleat, depending on the application.

BOFA HEPA filters are tested to filter 99.995% @ 0.3 microns.

Chemical/Gas filters

BOFA’s advanced carbon filters are designed to help filter fumes, with specific carbon types matched carefully to industry applications.

Contaminated air must remain in contact with the carbon bed for a period of time, sufficient to help ensure that no contaminants or odours are emitted (‘dwell time’). Our product designs consider the balance between airflow rates and the type, depth and surface area of the carbon used, taking into consideration the contaminants associated with the application and helping to ensure that appropriate dwell times are achieved.

Our filters have been developed to help capture contaminants and odours, which help to reduce the risk of bypass and/or tunnelling.

Advanced carbon filter (ACF) technology

BOFA’s combined filters are a combination of a HEPA filter and a chemical / gas filter coupled together to create a compact, cost-effective and efficient solution, rather than having two separate filters.

Filter technology

A world leader in fume and dust extraction systems

At BOFA, we design, develop and manufacture fume and dust extraction systems for a wide range of industrial sectors and applications. Our products play a very important part in helping to keep a clean, workplace environment.

Are you compliant?

Our expertly trained P601 qualified engineers help customers meet their obligations when it comes to LEV testing.

Find an extraction system to suit you

Our extraction technologies help to meet or exceed the standards set by health and safety legislation around the world… search for the right one for your needs.