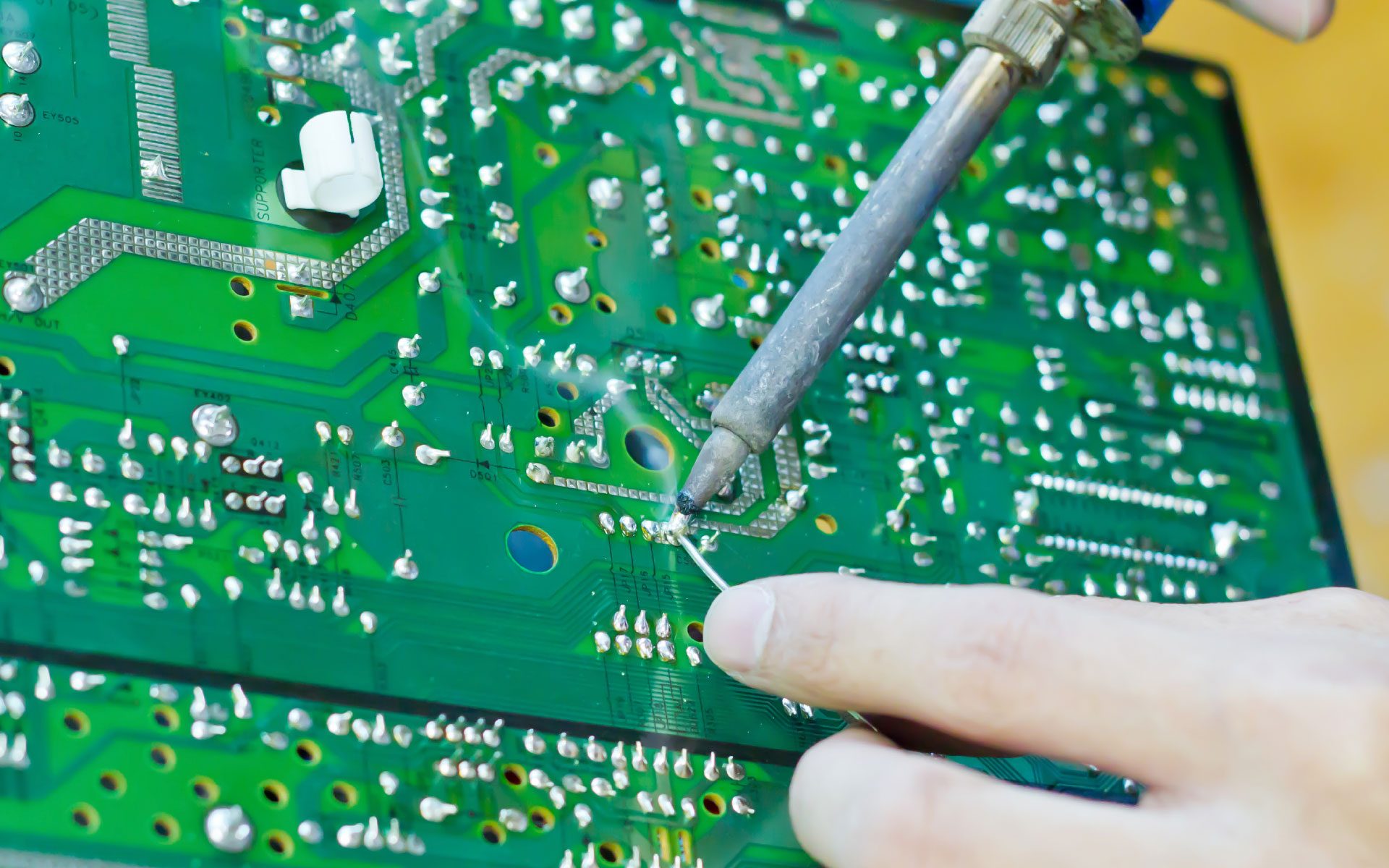

Our solder fume extraction systems are designed for single or multiple-operator stations that may generate fume comprising resin particulate and gaseous organic compounds.

Solder flux fume is recognised as a top cause of occupational asthma (Hse.gov.uk. 2022. Solderer – common causes of asthma – HSE. [online] Available at: https://www.hse.gov.uk/asthma/solderers.htm [Accessed 1 February 2022].), therefore understanding and controlling this hazard can be a key part of any health and safety programme.

Our range comprises two types of systems: tip (‘T’) extraction, for high pressure/ low airflow soldering processes; and volume (‘V’) for low pressure/ high airflow electronics processes, with features including three-stage filtration, advanced airflow design and filter condition display that helps to keep a clean work environment and productivity high.

Unsure what system is right for you? Find out what systems are best suited to manual electronics processes here and automated electronics processes here.

Typical applications

Hand soldering

Automated soldering

Gluing/potting

Conformal coating

Why BOFA?

We're proud to be a market leader in fume and dust extraction and here are a few reasons why.

Extensive product range

Clean filter change

Portable, flexible, mobile

Ideal for changing factory demands.

Specially designed

Filters designed specifically for solder fumes.

Tailored

Tailored systems and installations on request.

Maximum efficiency

Flow control helps to ensure units operate at maximum efficiency.

Carbon filter

Carbon filter for effective absorption.

Training designed for you

Through the BOFA Academy you can participate in a series of free online training delivered by our knowledgeable team. We have a range of modules available, including modules to help you understand more about BOFA products and the importance of having the right fume extraction.