The high temperatures generated in some additive manufacturing processes could release gases and particles into the workplace environment.

BOFA’s 3D PrintPRO models and AM range provide filtration and atmosphere management solutions in compact units. Our units help to provide a clean print area and return filtered air into the workplace environment.

Unsure what system is right for you? Find out what processes our systems are best suited to here.

‘Print your own’ connectors

Typical applications

VAT polymerisation (SLA, DLP)

Laser powder bed fusion (PBF)

Binder jetting (BJ)

Sheet lamination

Material jetting (MJ)

Directed energy deposition (DED)

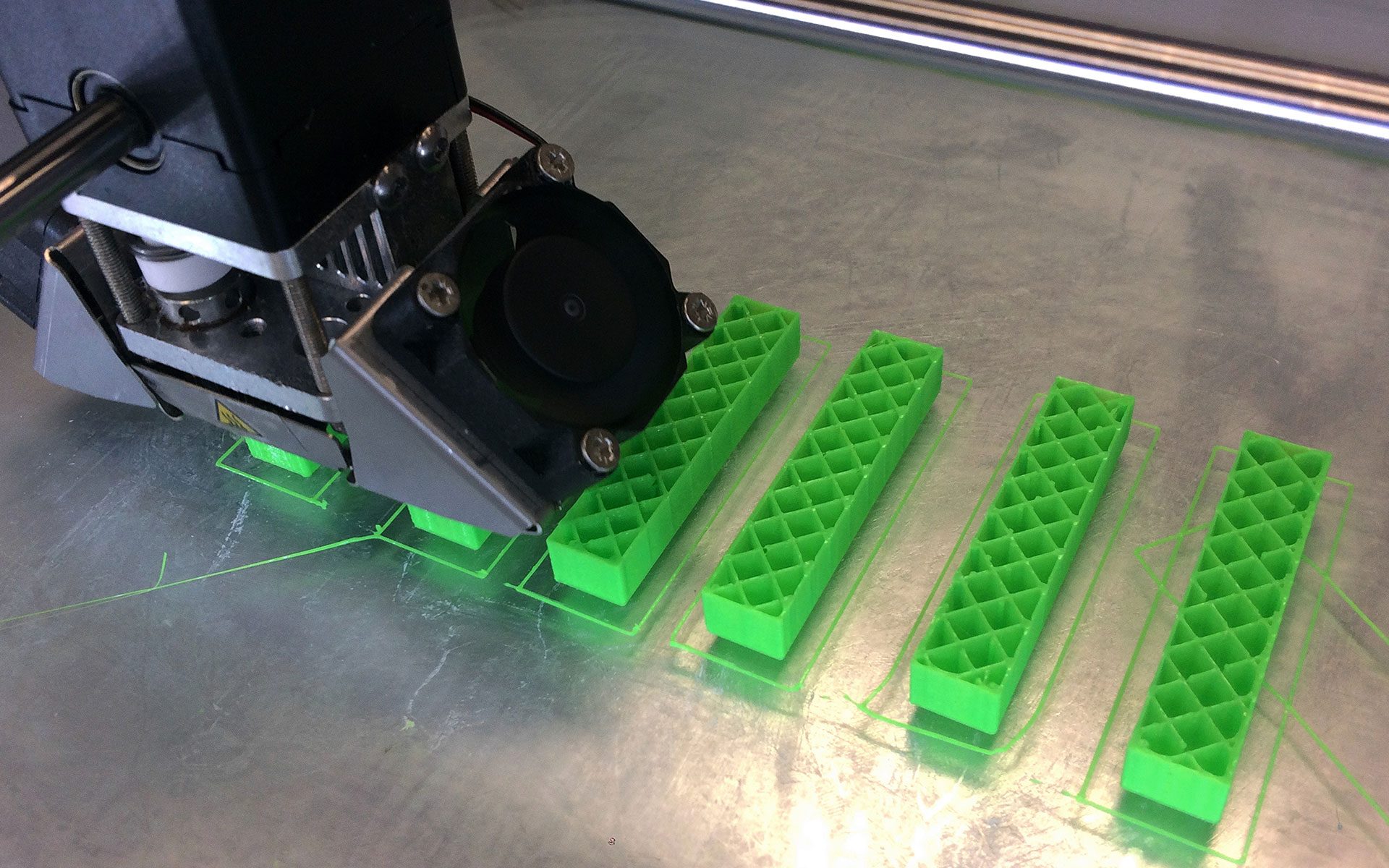

Material extrusion (FFF, FDM)

Post processing

Why BOFA?

We're proud to be a market leader in fume and dust extraction and here are a few reasons why.

Scalable units

A portfolio suitable for a wide range of applications.

Controlled gas flow

Precise control of gas flow that helps enable better quality processes.

Filter life

Remain compliant and increase productivity with BOFA’s long filter life.

Innovative products

Constant research and product development, driving product innovation.

Filtration expertise

Leveraging our network to maintain a validated portfolio of the latest filtration technology.

Tailored

Tailored systems and installations on request.

3D printing emissions: The basics

This technical paper considers the data and associated impact and control of 3D printing emissions.

Training designed for you

Through the BOFA Academy you can participate in a series of free online training delivered by our knowledgeable team. We have a range of modules available, including modules to help you understand more about BOFA products and the importance of having the right fume extraction.