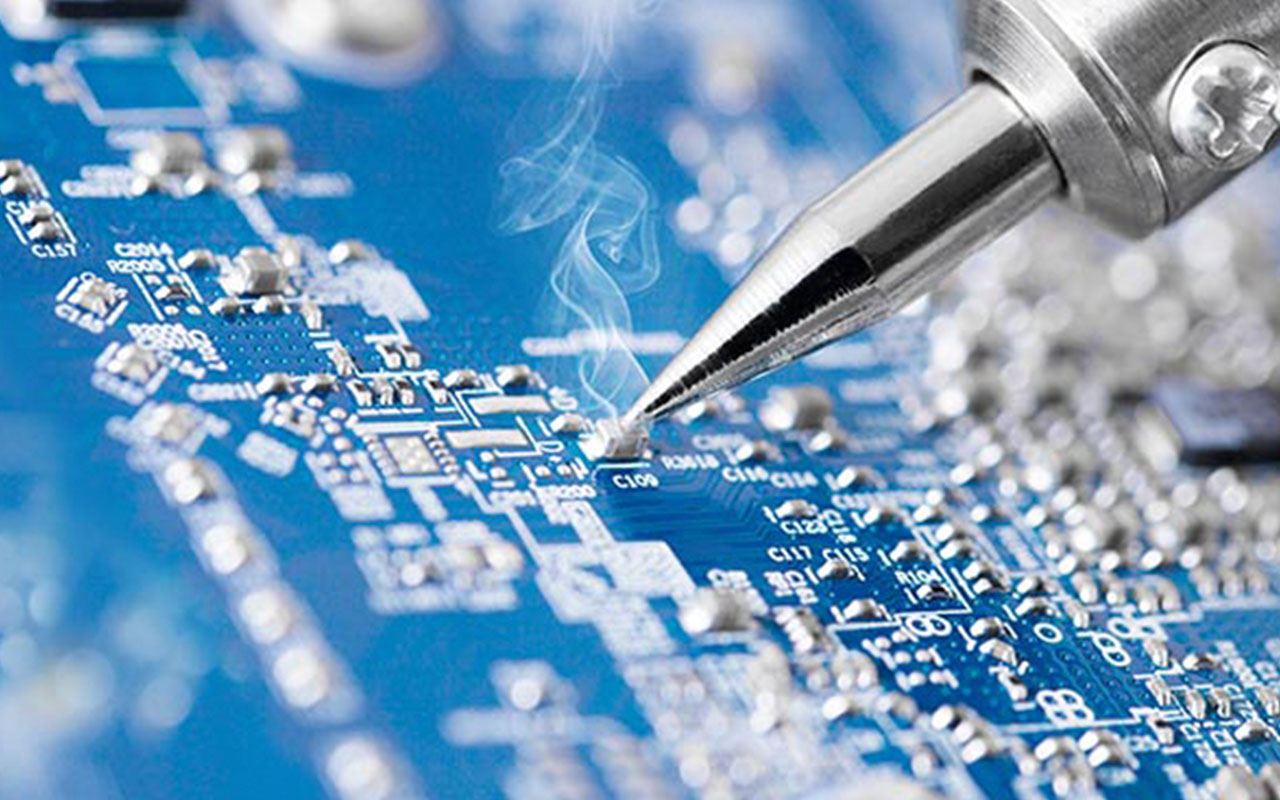

BOFA's range of Tip and Volume fume extraction systems are designed for electronics soldering applications that generate fume comprising; resin acid particulate and gaseous organic compounds.

Solutions are available for manual and automated processes including wave solder, reflow, selective solder and conformal coating applications.

T 1 and T 15

These tip extraction systems are designed for lead and lead-free soldering applications. These are high volume units that are designed to help extract and filter fumes and debris. The systems are ideally suited for soldering iron tip extraction, vac pens, flexi fume arms and any other number of applications that require close proximity micro extraction.

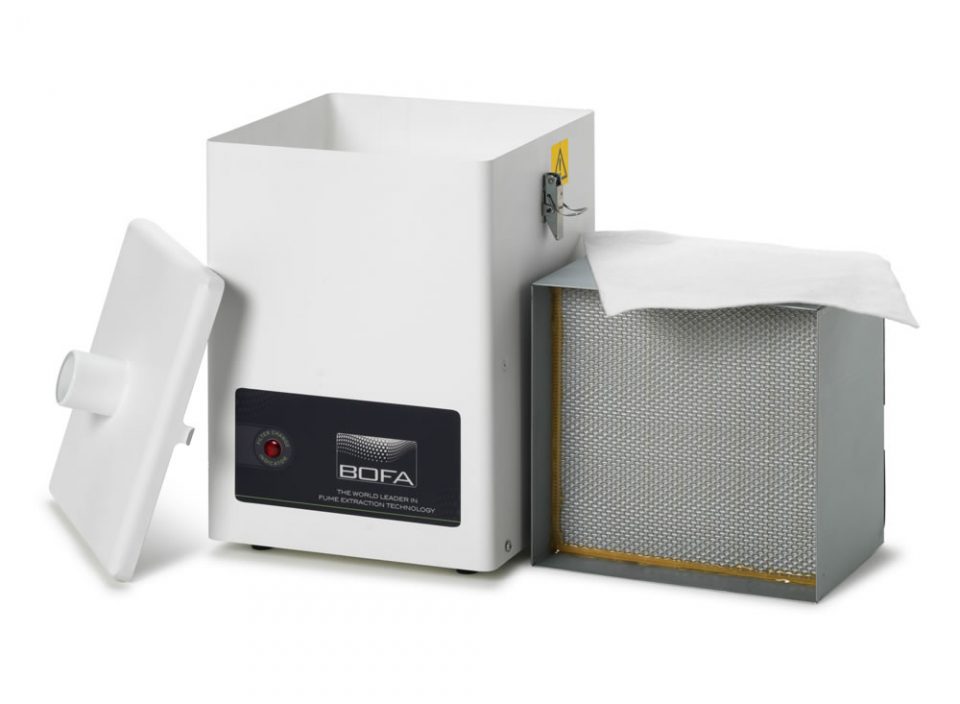

V 200 and V 250

Volume fume extraction units have been designed primarily to help extract the fumes generated during hand soldering in the electronics industry. These portable systems come complete with extraction arms and an installation kit that contain everything required to set up one or two operators with ease. Minimal installation allows the units to be moved with the workbench when factory layouts need changing due to production challenges. The low noise levels and fully comprehensive filtration units are ideal for factories with changing production demands.

Our larger volume extraction units have the capacity to be used on all manufacturers of automated soldering systems such as reflow ovens. Large filter capacity and vast carbon filters help to ensure long filter life and optimum extraction even when lead-free solder is used. Adjustable and regulated airflow control helps to ensure consistent temperatures within the solder machine/reflow oven, throughout the life of the filters.