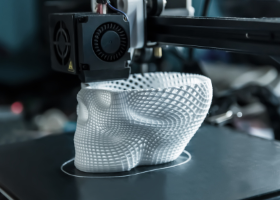

Making life better with 3D printing

From toucan beaks and F1 steering wheels to bespoke medical devices and ultra-comfy bicycle seats…life gets better when creativity, technical innovation and scientific endeavour are expressed through 3D printing.

Although additive manufacturing is not a novel production method, the range and type of applications is being transformed by process evolution and the invention of new generation functional materials. What started as a high-end prototyping methodology is now being employed on land, at sea and even in space, to customise products, reduce inventory costs, negate supply chain risks…and share the benefit of 3D print capability worldwide.

3D printing came to the fore of public consciousness during the pandemic, helping meet insatiable demand for medical equipment. Less well-known is 4D bioprinting which can create a stent for heart surgery or carry and deliver medicine to a specific area of the body. A custom scan of a person’s foot can be printed to form bespoke orthopaedic inserts, and if too much cycling becomes a literal pain in the backside, there’s a personalised 3D printed bike seat solution for that as well.

Whether it’s bio-print, edible print or using formulations of resins or polymer resins, polymer filaments or metal and polymer powders, 3D printing has evolved its own production and post-processing ecosystem.

As a result, additive manufacturing technology providers are increasingly turning to BOFA to help filter fume and particulate emitted by materials processed at high temperatures needed to create properties such as tensile strength, flexibility, scratch and resistance, to name a few.

This is because filtration is an important contributor to effective atmosphere management. Recent BOFA research confirms a correlation between higher temperature processes and the potential for both materials off-gassing – which can be toxic and smelly – and an increase in particulate emissions. Filtering these emissions can help to provide a clean print area and return filtered air into the workplace, helping maintain product quality while supporting environmental health strategies.

As a result of its investment in R&D, BOFA is an established leader in 3D print filtration technology, with a line-up that includes the new 3D PrintPRO HT, designed specifically to meet growing demand for filtration at high temperatures. The system uses advanced electronics components, thermal insulation and innovative air management to deliver high levels of filtration performance in chamber environments up to 230oF (100oC).

BOFA has also developed post-processing capability, with its FumeCAB integrated filtration cabinets helping to remove solvent odours from associated product finishing.

All this innovation supports an industry that is rapidly growing around the world, in part thanks to the emergence of new materials but also due to the lead-time benefits of local production. For example, one major tractor OEM shares digital files to enable the local manufacture of components; navy fleets have invested in 3D print capability to obviate the need to dock for parts; and Porsche Cayman S enthusiasts can now print their own vehicle model at home from a file shared by the automaker.

As this trend continues, it seems likely that 3D printers and associated filtration technology will become established in all sorts of environments. So, look out for systems in hospitals, film studios, in space, garages, even in restaurants…and as part of rapid logistical deployments in response to humanitarian crises. If it’s possible to print a tortoise shell from corn-based plastics, who knows what’s next?