Pioneering the future of fume extraction

Our award-winning Intelligent Operating System (iQ) brings multiple performance enhancements for higher efficiency of extraction, individual filter status monitoring and integral design features that combine to deliver a lower cost of ownership.

Patented technology

Winner of the Queen's award

The iQ Operating System is a truly global product. One model caters the world over - and clear and simple real-time features ensure clarity and ease of use.

Get to know the iQ

How the iQ works

Sophisticated and advanced technology is inbuilt, providing a user-friendly and intuitive experience with data about the extraction unit's performance being easy to access and analyse locally or remotely from data downloaded via USB.

Minimise production downtime

iQ minimises the potential for interrupting production for unplanned filter changes as they can be planned at a time to minimise or eliminate interruption to production. This means business can continue as usual, while costly or time-consuming service call outs are avoided.

Maximise filter life

Independent filter monitoring means the user can obtain the real-time status of the pre-filter and combined (main) filters so they are only changed when they need to be. Pre-blockage warnings provide operators with plenty of time to prepare for change by identifying which filter needs replacing and when.

Meeting the demands of Industry 4.0

The iQ platform satisfies demands created by Industry 4.0 with current trends of automation and data exchange in manufacturing technologies. Efficiency checks can be made at any time and data about machines on multiple sites can be viewed in one place to enable centrally controlled optimisation and maintenance.

Easy to use

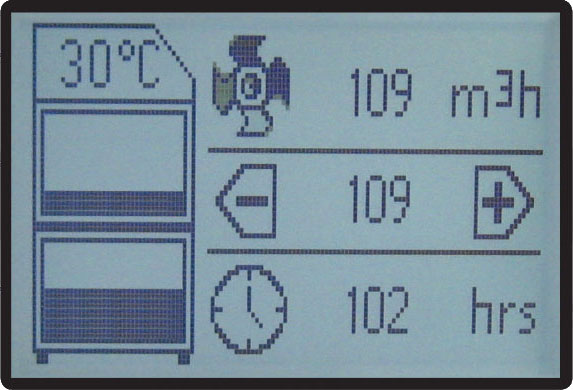

Sophisticated and advanced technology is inbuilt to the iQ so an intuitive experience is delivered. The easy to read black on white LCD control panel at the top of each unit sits on a sloping fascia so the real-time data is easy to view and real time performance and operational values are displayed in a clear and simple format. A user-friendly design is consistent across all iQ products for a more uniform look in environments where multiple units are in use.

Clear and precise information

The iQ utilises internationally recognisable symbols, making it easy to use, anywhere in the world.

Stay in control

Airflow reading / set point

Enables the installer to set the air flow rate to a known target value. The iQ will then automatically increase or decrease the fan speed to maintain this target airflow throughout the life of the filters. The display value can be adjusted by the end user and viewed in either M3/h or CFM.

Run hours

A visual counter displays the actual run hours of the motor ensuring meaningful data analysis can be undertaken.

Extraction running

The fan icon will rotate when the motor is running, indicating that the unit is operating correctly.

Temperature monitoring

The visual display indicates the temperature within the motor housing. The display value can be adjusted by the end user and viewed in either degrees Centigrade or Fahrenheit values.

Independent filter condition monitoring

The iQ uniquely incorporates multi-sensing technology to evaluate filter performance and status.

Pre-filter condition monitoring

A representative status ‘box’ icon of the pre-filter is displayed. The icon fills in parallel with the filter becoming blocked, giving the operator a real-time indication on the status of the pre-filter.

Combined (main) filter condition monitoring

A representative status ‘box’ icon of the main filter is displayed. The icon fills in parallel with the filter becoming blocked, giving the operator a real-time indication on the status of the main filter.

Warnings & alarm conditions

The iQ provides a series of visual, audible and electrical outputs to help ensure that all events are clearly communicated and that timely and appropriate intervention can be undertaken to maximise production uptime.

Filter status indicator (pre warning)

The 75% warning indicates that the filter is partially blocked and will shortly need to be replaced. An audible warning will sound and the representative filter status ‘box’ on the display will confirm which filter is affected. A signal output can be sent to the host.

Filter status indicator (warning)

The 100% warning indicates that the filter is blocked and needs to be replaced. An audible warning will sound and the representative filter status ‘box’ on the display will confirm which filter is affected. A signal output can be sent to the host.

Hose partial blocked (warning)

The hose partially blocked icon appears when a partial blockage occurs within the installation pipe work. A signal output can be sent to the host machine.

Hose blocked warning

The hose blocked icon appears when a blockage occurs within the installation pipe work. A signal output can be sent to the host machine.

Filter fire containment

In the extremely rare event that a filter fire should occur the unit will automatically cut off the airflow to suppress and contain the fire.

Remote diagnostics via USB connection

The run hours based event log provides easy access to a series of key performance metrics, enabling simple performance analysis and fast identification of likely fault and corrective action to minimise down time.

“Black Box” event log

In the event of a catastrophic failure the activity log and set up parameters can be retrieved via the USB connection. Data can then be used to support a reinstall and failure investigation.

Remote configuration

Factory set values can be adjusted to end user specifications.

Performance evaluation

Operating data can be downloaded via the USB connection to support evaluation and reporting. The data is automatically imported into a spreadsheet from which graphs can be created.

Universal features include:

Suitable for a broad range of applications

Auto sensing for multi voltage power

Internationally recognisable icons

Temperature viewable as °C or °F

International accreditation

Simple installation

Simple to use

Easy to support

Multi language manual