3D printers are large investments for any business, so it's important to maximize returns wherever possible.

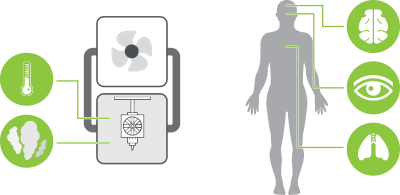

Use the opportunity to both protect the user and improve your part quality.

TAKE ACTION TODAY TO HELP IMPROVE YOUR ROI

The average price of industrial 3D printers is rising, with new technology, materials and faster processes demanding a higher price point. Additionally, with technology moving so fast – companies are spreading the capital expenditure of their machines over shorter and shorter time frames. It has never been more important to improve your return on investment by improving the quality of the parts printed and extending the life of your printer.

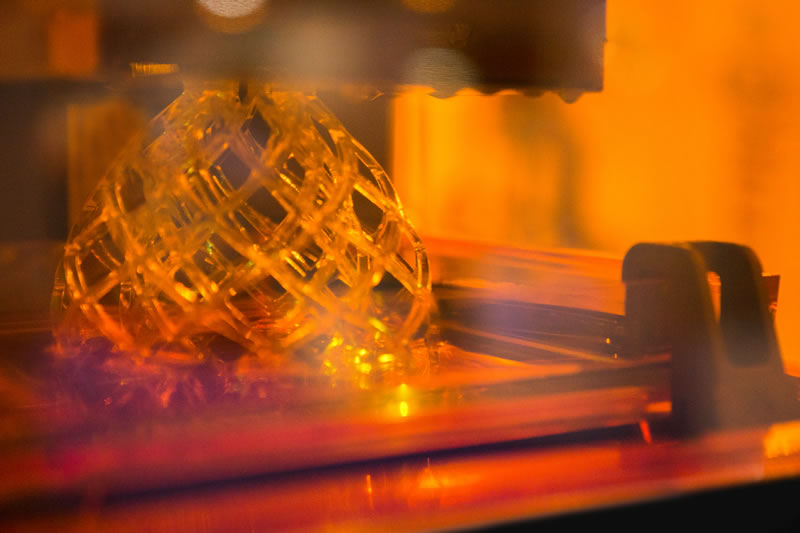

Thermal management

Open loop

A configuration in which the BOFA system is pulling air from within the 3D printer, filtering, then pushing into the local environment. This configuration results in a net heat loss from within the 3D printer. This setup can be advantageous when attempting to keep air temperatures lower than otherwise would be found when printing without extraction.

Closed loop

A configuration in which the BOFA system is pulling air from within the 3D printer, filtering, then pushing back into the 3D printer. This configuration results in heat stability or increases within the 3D printer. This setup can be advantageous when attempting to keep air temperatures higher or more stable than otherwise would be found when printing without extraction.

Both configurations can help improve thermal gradients during 3D printing, depending on what is being printed and by which process. With tighter control of thermal gradients, one has better control over quality-related issues such as distortion and strength loss.

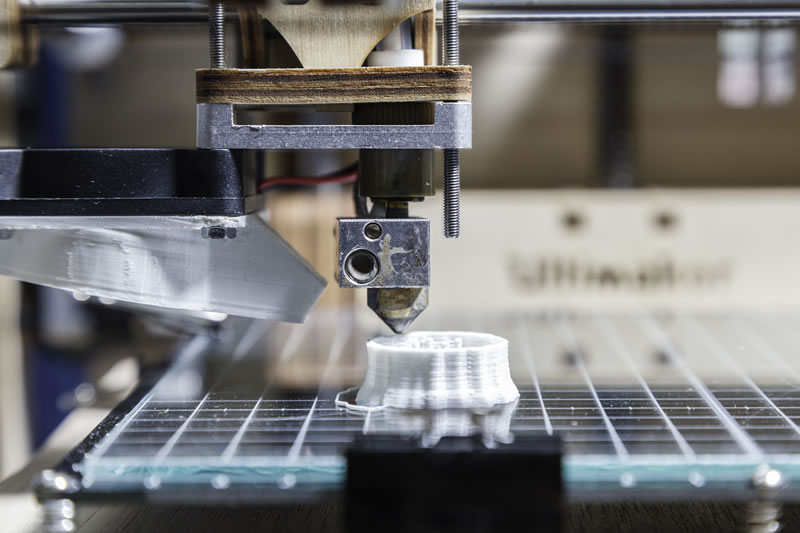

Contamination of machinery

Industrial 3D printer prices are increasing and with a higher price point, one can expect a higher-performing printer with better quality and increased productivity. To help reach optimum levels of productivity, one must decrease the downtime of the printer. Two of the biggest contributors to downtime of any printer are unexpected failure of componentry and maintenance. Though BOFA cannot help with all potential causes of downtime, a good extraction system can help reduce maintenance frequency and increase machine durability.

See below processes for how BOFA can help in each:

How can BOFA help you?

Using effective fume extraction and filtration systems can help avoid the risk of costly health and safety litigation for the employer; maintains the reliability of the machine, and protects operators from potentially harmful fumes.

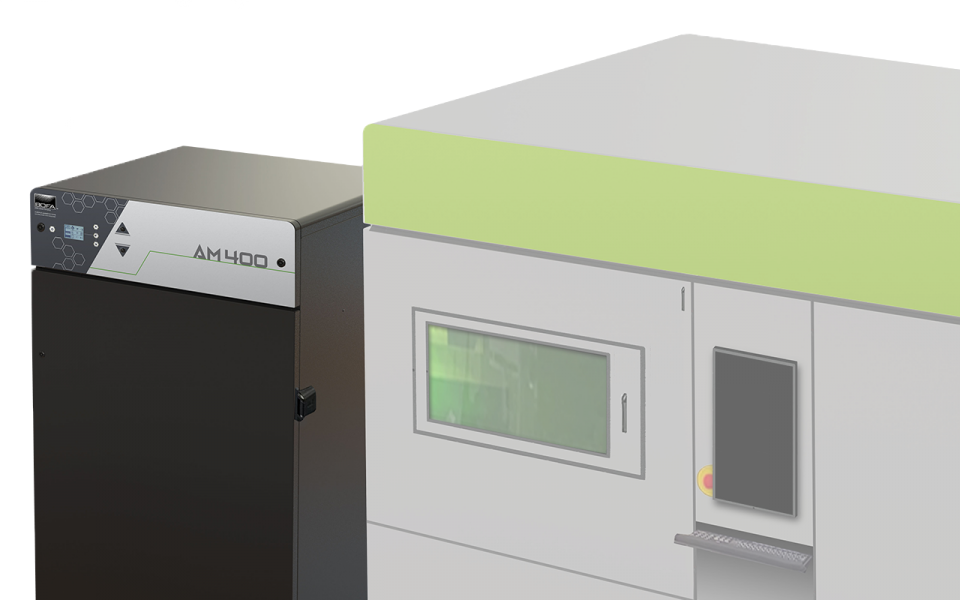

Our team of industry and application experts have developed systems specifically for the additive manufacturing / 3D printing sector.

Regardless of the size of process you are working with, BOFA has the system you need.