Dental milling dust and fume extraction systems

DG Shape dental milling machines

Designed for the DWX range of DG Shape dental milling machines.

DentalPRO range.

DentalPRO 400

Designed for the Roland DWX range of CAD/CAM dental dry milling machines.

BOFA’s DentalPRO 400 under bench portable dust extraction system filters dust and particulates generated during the hand finishing of dental implants.

The DentalPRO 400 is ideally suited to manual bench top applications, where technicians need to be able to work without restriction, but in the knowledge that dust particles are being filtered to help maintain a safer working environment.

The high vacuum pump used in the DentalPRO 400 is brushless and designed for continuous running to in excess of 30,000 hours before requiring servicing. The bag filter has a large 6.4 litre capacity and the HEPA filter is very high-efficiency.

This multi user system combines maximum operator protection in a small footprint, easy to operate unit with low running costs.

DentalPRO Universal

Designed for the Roland DWX range of CAD/CAM dental dry milling machines.

BOFA’s DentalPRO Universal portable extraction unit has been developed to work with the Roland DWX range of milling machines.

The unit's high-efficiency two stage filtration system filters dust particles generated in the production of dental implants and helps to ensure that the laboratory environment remains clean.

The compact and space saving design enables the unit to be easily and conveniently located.

DentalPRO Base DWX

Designed specifically for the Roland DWX50 - 'Ride-On' unit with optional onboard compressor.

BOFA's DentalPRO Base DWX 'Ride-On' dental extraction unit has been developed specifically for Roland's DWX range of dental milling machines.

The units high-efficiency two stage filtration system filters dust particles generated in the production of dental implants and helps to ensure that the laboratory environment remains clean.

The DentalPRO Base DWX extractor has mounting positions so a Roland DWX machine can be securely placed onto of the extraction unit doubling up as a space saving stand.

The onboard compressor option provides the miller with clean oil-free air.

DentalPRO Base DWX52-DCi

Designed specifically for the Roland DWX52-DCi - 'Ride-On' unit with optional onboard compressor.

'Ride on' dust extraction system for the DG Shape DWX52 DCi dental

CAD/CAM dry milling machine.

BOFA’s DentalPRO Base DWX52-DCi dental dust extraction unit has been developed specifically for the DG Shape DWX52-DCi dental milling machine, which sit on top, allowing the extraction unit to double up as a space saving stand / bench, with internal storage space.

The unit’s high efficiency two stage filtration process allows technicians to work safer in the knowledge that dust particles are being effectively filtered, to help maintain a cleaner working environment. The bag filter has a large 18 litre capacity and the HEPA filter has an efficiency of 99.995% at 0.3 microns. The high vacuum pump is brushless and designed for continuous running for longer periods of time before requiring servicing.

An added optional extra is an onboard compressor, providing the miller with clean oil-free air for all compressed air requirement, with a built in water trap relief valve pipe and internal container.

Milling and Engraving dust and fume extractor systems.

DG Shape CNC milling machines.

Designed for the EDX and MDX range of DG Shape CNC milling machines.

DustPRO range.

DustPRO 50

Industrial particle and dust extraction system designed specifically for the Roland EGX.

BOFA’s DustPRO 50 portable dust extraction unit has been developed to work with the Roland EGX desktop engraving machines. Developed for the filtration of swarf and smaller particulates during the milling process.

One of the main problems with other router extraction relates to the type of pump used. Most have brushed motors, which are noisy in operation and frequently burn out, with the average life of brushes being around 800 hours.

The pump used in the DustPRO 50 is brushless and designed for continuous running to in excess of 30,000 hours before requiring servicing. They generate high vacuums and are quiet in operation. The large capacity bag filter has a high-efficiency.

DustPRO 50

Industrial particle and dust extraction system designed specifically for the Roland MDX.

BOFA’s DustPRO 50 portable dust extraction unit has been developed to work with the Roland MDX40A small bench top milling machine. Developed for the filtration of swarf and smaller particulates during the milling process.

One of the main problems with other router extraction relates to the type of pump used. Most have brushed motors, which are noisy in operation and frequently burn out, with the average life of brushes being around 800 hours.

The pump used in the DustPRO 50 is brushless and designed for continuous running to in excess of 30,000 hours before requiring servicing. They generate high vacuums and are quiet in operation. The large capacity bag filter has a high-efficiency.

DustPRO Universal

Industrial particle and dust extraction system designed specifically for the Roland MDX540.

BOFA’s DustPRO Universal (Milling) extraction unit has been developed to work with the Roland MDX540 large bench top milling machine.

The unit’s high-efficiency two stage filtration system filters dust particles generated during processes such as routing, mechanical engraving, grinding and turning. The compact design enables the unit to be easily located under a bench or worktop.

Printing fume extractor systems

PrintPRO Universal

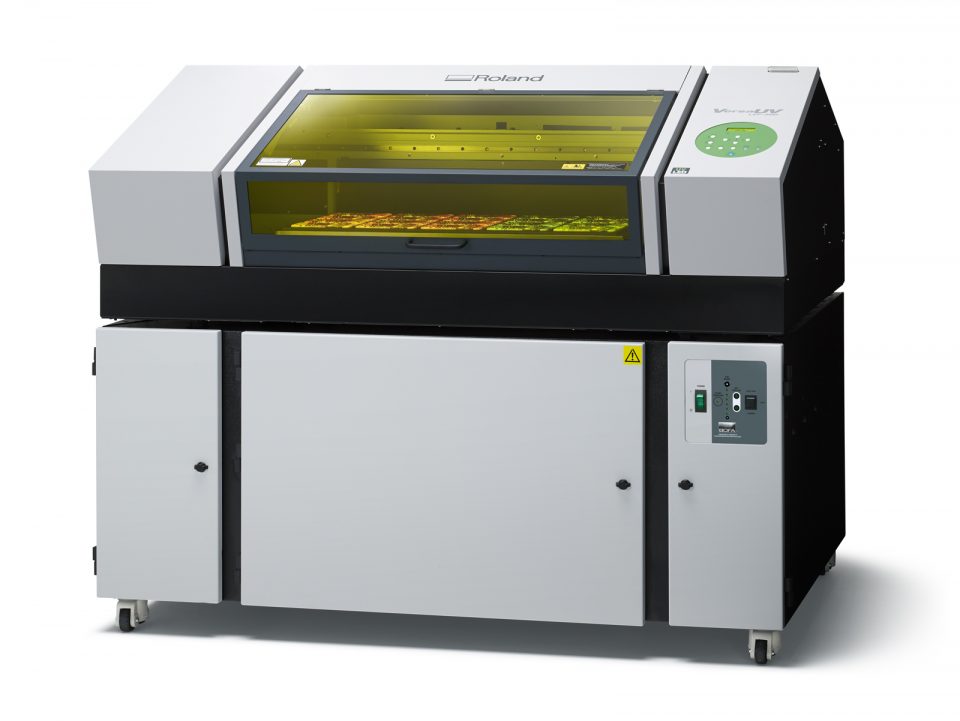

Fume extraction system for the Roland LEC, LEJ and AJ series printers.

Recommended by Roland DG as the choice of print fume extraction for the LEC, LEJ and AJ Series printers.

BOFA’s pioneering extractor, the PrintPRO Universal was designed exclusively for the fume extraction on the Roland LEC, LEJ and AJ printers. The PrintPRO Universal’s unique features help enable it to filter a wide range of solvents generated within printing environments, including MEK, Ketones and Ozone from UV applications.

The PrintPRO Universal is easily adapted to a huge range of environments, including wide format printing, inkjet coding printers (CIJ) (both solvent and UV) and numerous other applications.

PrintPRO LEC2

Fume extraction system for the Roland LEC2 printers.

BOFA’s latest extractor, the PrintPRO LEC2 has been designed exclusively for the Roland LEC range of printers. The system’s unique features enable it to effectively filter a wide range of potentially hazardous solvents generated within these environments, including MEK, Ketones from UV applications.

The PrintPRO LEC2 is easily adapted to a huge range of environments, including wide format printers, inkjet coding printers (CIJ) (both solvent and UV) and numerous applications such as UV coating.

PrintPRO Base LEF 12

Fume extraction system specifically designed for the Roland LEF 12 and 12i printers - 'Ride-On' unit & colour matched.

Recommended by Roland DG as the choice of print fume extraction for the LEF Series printers.

BOFA’s PrintPRO Base LEF 12 is designed exclusively for Roland DG to filter odours generated during the printing process.

The design allows the Roland LEF12 and 12i printer to sit on top of the extractor as a cart or bench, and specially formed dimples to help ensure a perfect alignment and secure location. Manufactured to run efficiently and quietly in an office environment, colour matched for good looks, with practical internal storage and castors for portability, the PrintPRO Base LEF 12 is the perfect companion to the Roland LEF12 and 12i Printers.

PrintPRO Base LEF 20

Fume extraction system specifically designed for the Roland LEF 20 and 200 printers - 'Ride-On' unit & colour matched.

BOFA's PrintPRO Base LEF 20 is designed exclusively for Roland DG to remove odours generated during the printing process.

The design allows either the Roland LEF-20/200 printer to sit on top of the extractor as a cart or bench, and specially formed dimples ensure a perfect alignment and secure location. Manufactured to run efficiently and quietly in an office environment, colour matched for good looks, with practical internal storage and adjustable castors for portability, the PrintPRO Base LEF 20 is the perfect companion to the Roland LEF-20 / 200 printers.

PrintPRO Base LEF2-200

Fume extraction system specifically designed for the Roland LEF2-200 and 200 printers - 'Ride-On' unit & colour matched.

Recommended by Roland DG as the choice of print fume extraction for the LEF Series printers.

BOFA’s PrintPRO Base LEF2-200 is designed exclusively for Roland DG to filter odours generated during the printing process.

The design allows either the Roland LEF2-200/LEF-200/LEF-20 printer to sit on top of the extractor as a cart or bench, and specially formed dimples to help ensure a perfect alignment and secure location. Manufactured to run efficiently and quietly in an office environment, colour matched for good looks, with practical internal storage and adjustable castors for portability, the PrintPRO Base LEF2-200 is the perfect companion to the Roland LEF2-200 / LEF-200 / LEF-20 printers.

PrintPRO Base LEF 300

Fume extraction system specifically designed for the Roland LEF 300 printer - 'Ride-On' unit & colour matched to the LEF300.

Recommended by Roland DG as the choice of print fume extraction for the LEF Series printers.

BOFA’s PrintPRO Base LEF 300 is designed exclusively for Roland DG to filter odours generated during the printing process.

The design allows the Roland LEF300 printer to sit on top of the extractor as a cart or bench, and specially formed dimples to help ensure a perfect alignment and secure location. Manufactured to run efficiently and quietly in an office environment, colour matched for good looks, with practical internal storage and adjustable castors for portability, the PrintPRO Base LEF 300 is the perfect companion to the Roland LEF300 Printer.

PrintPRO Base SF 200

Fume extraction system and stand for the Roland SF-200 eco-solvent printer.

BOFA's PrintPRO Base SF-200 is designed exclusively for Roland DG to remove odours generated during the Roland SF-200 eco-solvent printing process of sensitive applications.

The fan assisted individually PID temperature controlled heated draws allow printable parts to be warmed to exact temperatures before printing and cured afterwards in safety and within a filtered environment, improving ink adhesion to the material and degassing.

The design allows the Roland SF-200 printers to sit on top of the extractor as a cart or bench, and specially formed dimples ensure a perfect alignment and secure location. Manufactured to run efficiently and quietly in an office environment, colour matched for good looks, with practical internal storage, adjustable castors for portability and 3 modes of operation, the PrintPRO Base SF-200 is the perfect companion to the Roland SF-200 eco-solvent printer.

Laser fume extraction systems

LV180 Lite

Fume extraction system for the Roland LV-180 laser engraver / cutter.

The LV180 Lite fume extraction and filtration system filters potentially harmful fumes and particulates created during the laser marking process. By maintaining a dust-free operating area, the system helps to protect valuable equipment, maintain a higher quality mark, and reduce the number of rejects and contaminants.

The quiet and compact LV180 Lite is ideal for use in light duty laser marking applications, including schools, sign making workshops and small scale industrial environments.

BASE LV180

Fume extraction system for the Roland LV-180 laser engraver / cutter.

The Base LV180 has been designed so that the Roland LV-180 engraver can sit on top of the extractor, doubling up as a work station. BOFA’s ‘Easi-Seal’ filter location makes filter change easy, quick and safer.

The revolutionary auto-voltage sensing turbine automatically self adjusts to run on any voltage worldwide, while the Reverse Flow filter technology enhances filter performance and helps to ensure longer filter life.

Automatic Flow Control allows the user to preset correct flow rates, giving lower noise levels and further protection of both the combined filter and the patented DeepPleat DUO pre-filter.

LV-Pro

Fume extraction system for the Roland LV-180 and LV-290 laser engravers / cutters.

The LV-Pro has been enhanced with BOFA’s Operating System (iQ), combining a range of unique features into one compact unit.

The iQ Operating System performs at two distinct levels. Operators benefit from ease of operation and clarity of real-time information, the system also provides a cache of analytical data, enabling users to download performance and operating parameters for evaluation purposes.

The iQ system takes performance and safety parameters to a new level and helps to ensure that maintenance downtime and ownership costs are kept to a minimum.

More information about the Intelligent Operating System (iQ).

LV290 Max

High performance laser fume extraction system for the Roland LV-290 laser engraver / cutter.

The LV290 Max high end laser extraction system combines extremely large filter capacity with high airflow and pressure rates, making it the ideal choice for heavy duty applications that generate large amounts of potentially harmful fumes, particulates and gaseous organic compounds.

Performance is enhanced with the inclusion of several features including BOFA’s patented DeepPleat DUO pre-filter and the acclaimed Intelligent Operating System (iQ). These take performance and safety parameters to a new level and help to ensure that maintenance, downtime and ownership costs are kept to a minimum.

More information about the Intelligent Operating System (iQ).

World leaders and your Solutions Partner for Roland dental, milling and printing systems.

BOFA International is acknowledged as a world leader in the design, manufacture and supply of portable fume extraction and filtration units and systems. BOFA products are used in a wide range of manufacturing processes, including Laser, Electronics, Additive Manufacturing / 3D printing, Mechanical engineering, Printing, Dental, Medical and Pharmaceutical.

“In all market sectors in which we operate, we develop close working partnerships with OEMs and distributors.“

Tony Lockwood, Managing Director

BOFA portable fume and dust collector / extractor systems

There are many more BOFA fume extraction systems available for whichever industry you are involved. If you need any guidance in which portable fume extractor to choose, please contact us and we will gladly point you in the right direction.

BOFA service and filters

BOFA offer support and service for LEV (Local Exhaust Ventilation) testing in the UK, to help ensure compliance with the latest Health and Safety Executive COSHH regulations under HSG258 guidelines and are committed to providing reliable, simple to use, cost effective systems that meet and often exceed health and safety legislation worldwide.

Helping you maintain a clean, healthy working environment

BOFA develop, manufacture, supply and install high performance portable fume and dust extraction and filtration systems and have unrivaled knowledge in the development and production of the latest fume extraction technology systems, creating units for every industry and application.