While the occurrence of a fire or thermal event within a laser process is rare, it’s best practice to have well-implemented procedures and equipment in place to help further reduce the risk.

We’ve put together some guidance on managing and controlling the risk of a potential thermal event within your laser process. There may be additional factors about an individual application, user risk assessment and/or local regulations that supersede or negate it which must also be taken into account.

Donaldson does not assume any responsibility or liability for any loss or damage that may occur as a result of any fire hazard.

Managing and controlling risks

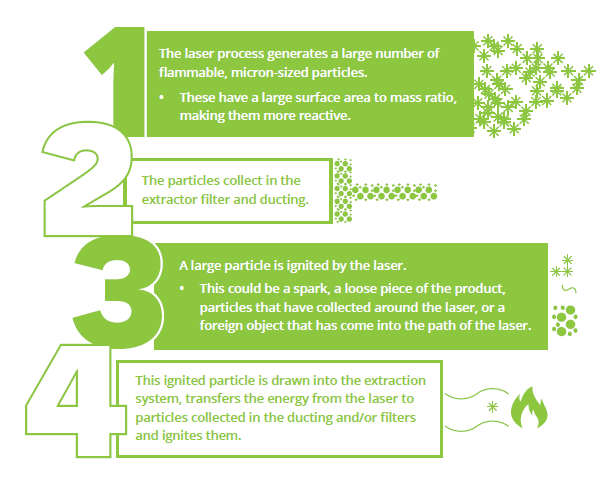

The stages of a thermal event developing within a laser process are usually as follows:

Procedures

• A risk assessment should always be the first step in the health and safety process. This will help identify the potential risks, if they can be avoided entirely (i.e., can materials be changed, etc.), and what follow-up actions are required.

• Training helps operators understand the risks associated with their work, the importance of maintaining safety procedures/equipment. Having a maintenance schedule in place to keep the laser area and ducting clean helps to reduce the risk of the laser coming into contact with flammable particulate. It may be appropriate to periodically change the ducting.

• Ensuring that your extractor filters are changed on time helps to reduce the amount of particulate available for a fire and having your extraction system maintained by a competent person reduces the risk of underperformance or malfunction.

• Correct procedures should be established and followed in the event of a fire (e.g., not opening the extractor door and exposing the fire to fresh oxygen). Operators should also know where the nearest fire extinguisher is situated and how to use it.

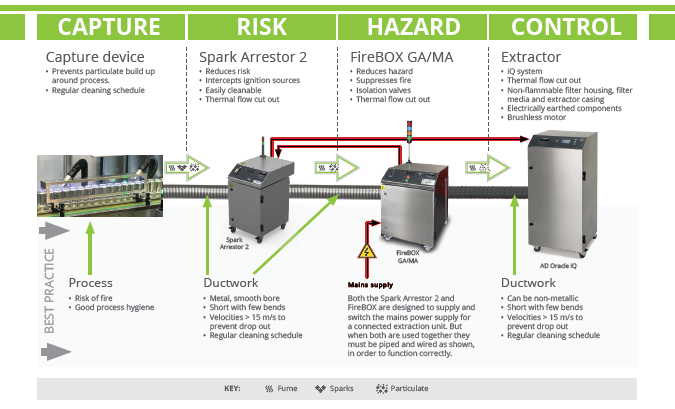

Extractor Installation

• Having good fume capture helps to reduce the build-up of particles around the laser area which in turn, helps to reduce the risk of particles being ignited by the laser.

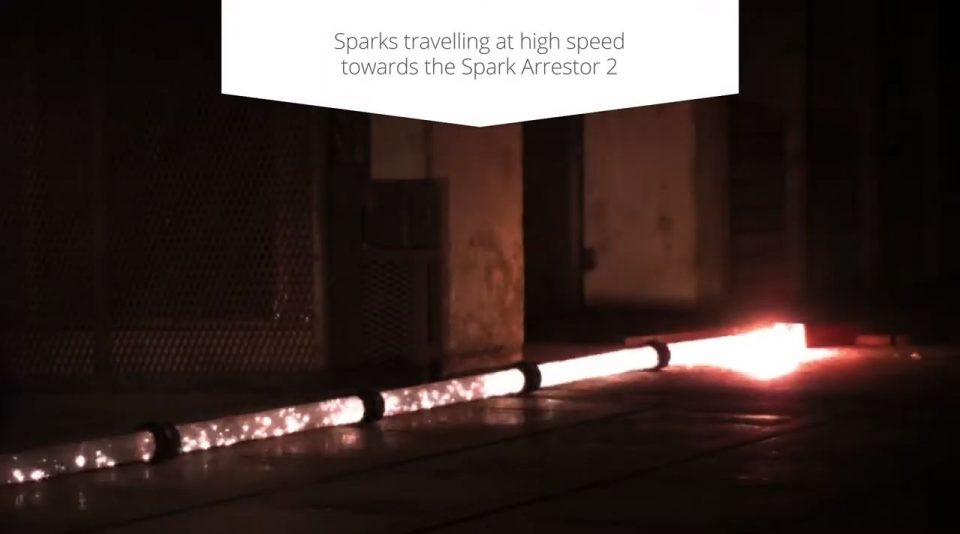

• Ducting should be designed in a way that reduces the number of bends, lengths, and build-up of particles. For many countries, the minimum duct velocity for laser fume is around 10 m/s, BOFA typically recommends increasing this to 15 m/s for applications where there is an elevated risk of fire. This duct velocity helps to reduce particulate drop out which gives the ignited particle more time to burn out before coming into contact with flammable material.

• Duct material should be selected in accordance with the risk. For fire, BOFA would typically recommend metal ducting or an appropriate fire-rated material (e.g., UL94 V-0).

• Ducting should be appropriately grounded to help prevent static build-up.

• The extraction system should have a temperature sensor that can detect a fire, alert the operator, and cut power to the extractor to reduce the supply of fresh oxygen if necessary.

• Filters should be made of appropriately rated materials (e.g., UL94 V-0).

Effective systems for fume extraction and risk mitigation

At BOFA, we design, develop, and manufacture portable fume extraction and filtration systems for the laser industry. We create technologies that help to improve industrial process performance by minimizing disruption to production.

We’ve been building innovative, award-winning systems for over 35 years and work closely with you to help ensure you get the appropriate system.

Mitigating equipment

The risk assessment should determine whether the below equipment is necessary. The Spark Arrestor 2 and FireBOX MA/GA must be used with an extraction system; they can be used individually or together in front of the extraction system.

Spark Arrestor 2

Designed to help reduce fire risks in

laser processes by capturing the larger particles and dissipate their heat. If the temperature sensor inside the Spark Arrestor 2 detects a 10°C rise above the ambient, it will sound an alarm and cut power to the extractor.

FireBOX MA/GA

Designed to help reduce fire hazards by extinguishing fires

when it detects them. If the FireBOX detects a 10°C rise above the ambient, power to the extraction system shuts off and the isolation

valves on the inlet and outlet close. If a further 10°C rise is detected (20°C total), the fire suppression system will be activated.