We asked the question and you answered...

‘We don’t need fume extraction’

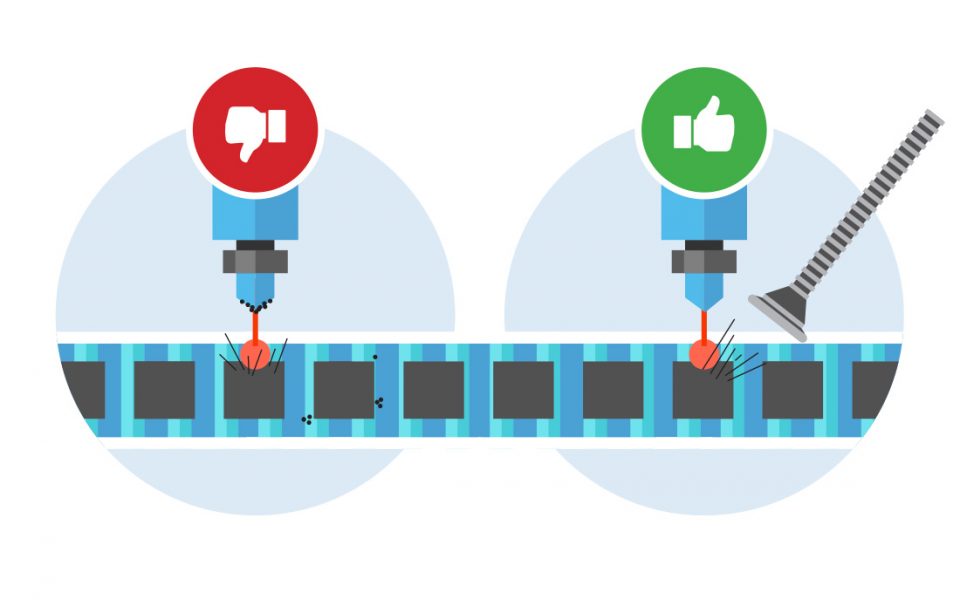

Before you disregard the need for laser fume extraction, let us guide you through some questions to ask yourself.

When did you last get your requirements scoped?

Have your process changed at all since your requirements were last scoped?

Have you got a new laser? Are you processing new materials?

types of laser fumes

Whether lasers are running in a school or a large-scale factory, all airborne substances must be considered as potentially harmful:

Cutting, coding and marking, engraving, welding…whatever the laser process, some form of contaminant is generated which can become airborne. They may be solid particles, gas or vapour. Most are invisible to the naked eye. All must be treated as hazardous.

- Inhalable

- Respirable

Select type

How can fume extraction benefit you?

Examples of processes that require fume extraction:

Laser coding and marking

Laser engraving and cutting

Laser welding

PVC

Precious metals

Ride on extractors

Cooling units

Chat to an expert today

If you are working with an unusual or new material, our highly qualified Applications Specialists can work out what you need.

Still not convinced?

Download our FREE quick guide to the benefits of having fume extraction.

Search our systems

Find the right extraction system for you