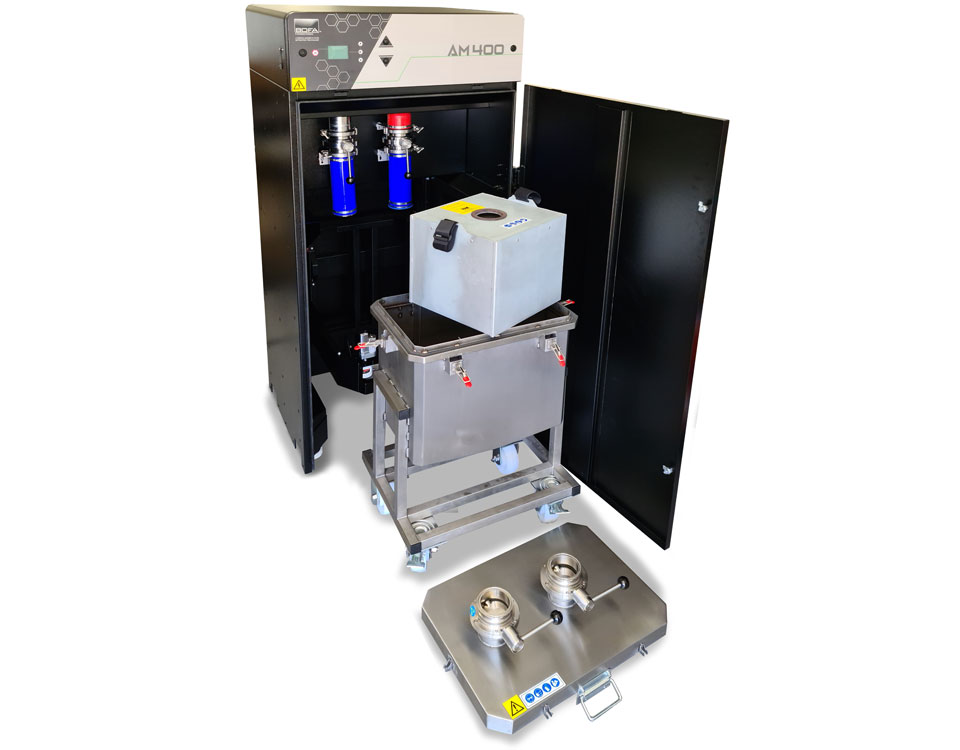

AM 400

AM 400

Designed and built specifically for inert particulate filtration, the AM 400 is the premium extraction solution for the additive manufacturing industry.

It offers benefits to users in direct metal laser sintering and selective laser melting polymer applications.

Is this the system for you?

Let our knowledgeable team support you in choosing the most appropriate system for your requirements.

We offer a range of accessories for many of our units

Please refer to our accessories page for further information and then get in touch with our experts to define exactly what you need.

Key features of the AM 400

Intelligent Operating System (iQ)

DeepPleat DUO pre-filter

Automatic flow control (AFC) Technology

Reverse flow air (RFA) technology

Patented technology

Low leakage

This unit is very low leakage:

<33ml/min @-10mBar.

Limits argon loss.

Limits oxygen ingress.

Electronics lift assist

This unit has electronic lift assist for ease of housing installation and disassembly.

Electronic actuator which lifts the housing by 100mm, using the buttons on the front panel.

Lifts up to seal against the tri-clamp fittings.

Removable filter housing

This unit has a removable and isolatable filter housing element. This keeps the contents securely under inert conditions during transport.

Double seal arrangement which results in:

<15ml/min @-10mBar loss.

Limits argon loss.

Limits oxygen ingress.

Ergonomic height.

Robust and ruggedised castors.

DeepPleat DUO, patent protected drop-out chamber.

ProTECT service plan

SureCHECK quality standard

Technical specification

Reverse flow filter technology

Standard

F8 particulate filter

Standard

Realtime gasflow reading

Standard

Filter status warnings

Standard

Automatic flow control

Standard

High contrast display

Standard

Remote diagnostics via USB

Standard

Interfacing

Standard

Removable filter housing

Standard

Isolation valve

Standard

Electronic lift assist

Standard

Low leakage

Standard

Tri-clamp inlet & outlet connections

Standard

Upgrade to HEPA filter

Optional

Datasheet correct at time of publishing. For specific applications, please contact us for details.