Markets & applications

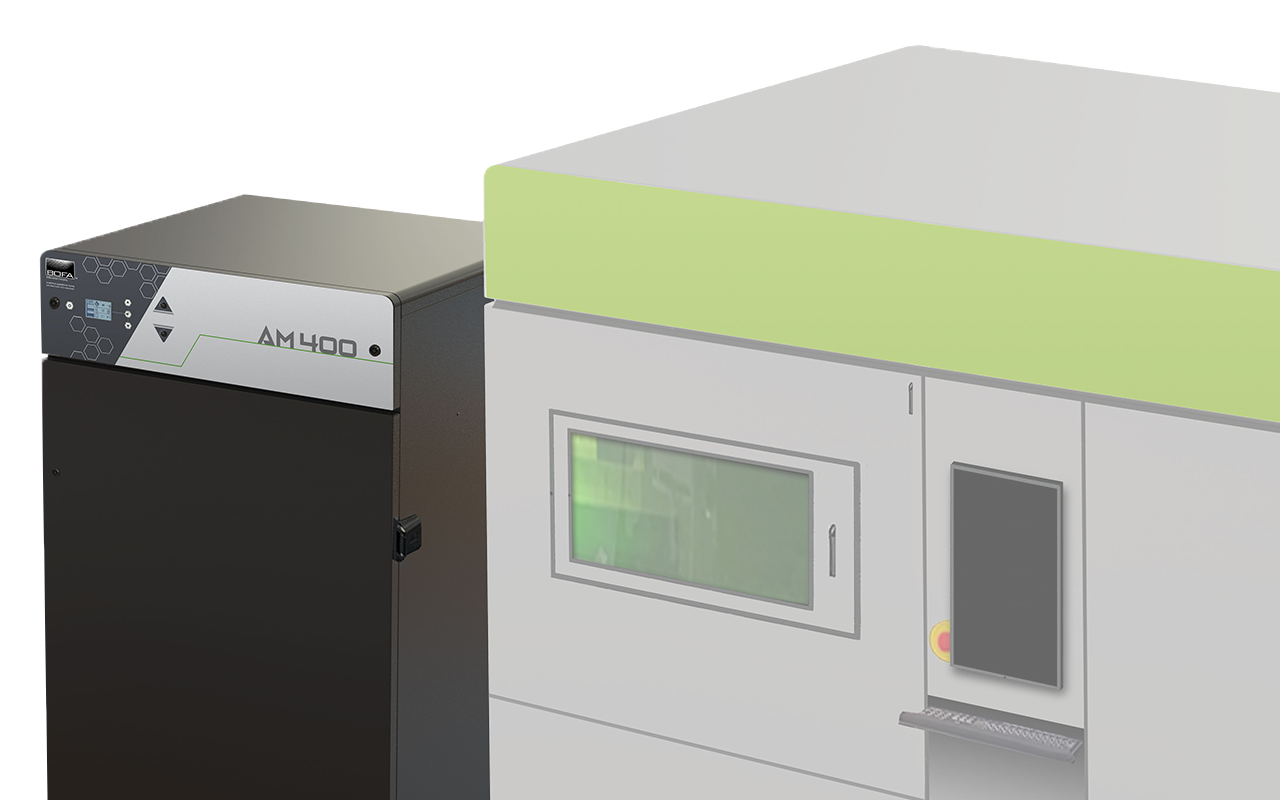

Designed and built specifically for inert particulate filtration, the AM 400 is a premium extraction solution for the additive manufacturing industry. It offers significant benefits to users in direct metal laser sintering and selective laser melting polymer applications.

Pharmaceutical | Nuclear | Aerospace | Aeronautical | Medical | High-value metal printing

BOFA delivers

Innovation in filtration

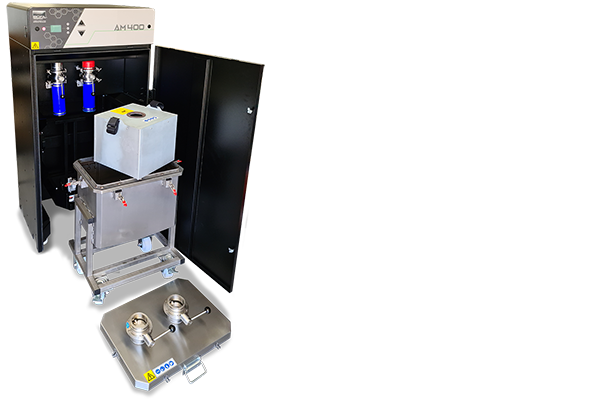

Exchange filters on-site, without risking a thermal event

Filters are contained within a separate housing, with a robust seal, enabling filter exchange to be completed quickly and safely in a location remote from the process floor. The long filter life significantly reduces the frequency of filter replacement, further increasing productivity.

BOFA delivers

Increased productivity and process quality

Designed in partnership with a leading additive manufacturing company

The AM 400 is part of BOFA’s significant investment in AM solutions, providing long filter life and a leak-proof sealed extractor. It delivers a range of benefits for OEMs in the 3D metal printing sector. We can also work in partnership with customers to create a customized solution.

BOFA delivers

Long-life filters, replaced with ease

The filter housing is completely removable, and the whole procedure can be performed on-site with minimal disruption.

The AM 400’s high-surface-area patented DeepPleat DUO filter delivers key benefits:

- Clean chamber environment

- Clear laser lens

- Higher quality process

- Protected equipment

- Helps protect people

Get the benefits

Inert welding

Higher productivity

Long filter life

Quick filter change procedure

(spare filter housings available)

Increased safety

Isolation valves

Removable filter housing

Ergonomic design

Lower cost of ownership

Low leakage (reduced argon spend)

Ease of use

Simple filter change procedure

Better quality of printed parts

Constant flow rate using iQ system

High-performance pump

Low leakage (low O2 ppm)

Get the benefits

Glovebox applications

Increased productivity

Long filter life

Quick filter change procedure

Increased safety

Low leakage

Isolation valves

Removable filter housing

Greater process control

Constant flow rate using iQ system

Better capture through high performance pump

Low leakage (low O2 ppm)

High flow rates

More system information

iQ filter monitoring

On-screen system information

Remote diagnostics

System alarms

Lower cost of ownership

Low leakage (reduced argon spend)

Improved communication

Interfacing capabilities from iQ system

Ease of use

Simple filter change procedure

Ergonomic design

Lift assist

Powered by iQ

BOFA’s award-winning, patented Intelligent Operating System (iQ) – a unique, intelligent system that provides versatile reporting and control for fume extraction.

- On-screen system alarms for easy identification of extraction problems

- Find the ideal flow rate for the AM 400

- Download log files to examine issues after the event

Book a call with our experts today

With vast experience in the field you can trust a BOFA representative to find you the right system for your needs.

Get the knowledge with our brochure pack

Learn more about the AM400 and how it can benefit your process.

Get your questions answered - contact us today

With offices around the world and experts on your doorstep we can help you meet your safety and productivity goals.

One size doesn’t fit all and BOFA can work with you to deliver a fume extraction system for your needs – contact us to find out more.