FGP Systems is a precision engineering company offering innovative, high-end solutions to the aerospace industry and other sectors.

At the forefront of their trade for over 45 years, FGP use the latest CAD/CAM systems, metrology equipment and 24-7 machining capability to support leading aerospace customers.

The Challenge

With a large proportion of work involving the use of hand fettling tools, FGP had an upcoming challenge with dust extraction from metal components. They approached BOFA for a solution to remove the dust particles so their employees could work in a healthy environment. FGP also had very specific requirements regarding the size of any system, for their operators’ ease of use.

The Solution

On our first visit to the site, we could see that while the main problem was the volume of dust from the metal, the way the employees operated - by holding the work piece close to their breathing zone - could also be improved.

We carried out early trials with our standard extraction cabinets to demonstrate to FGP airflows and required extraction rates.

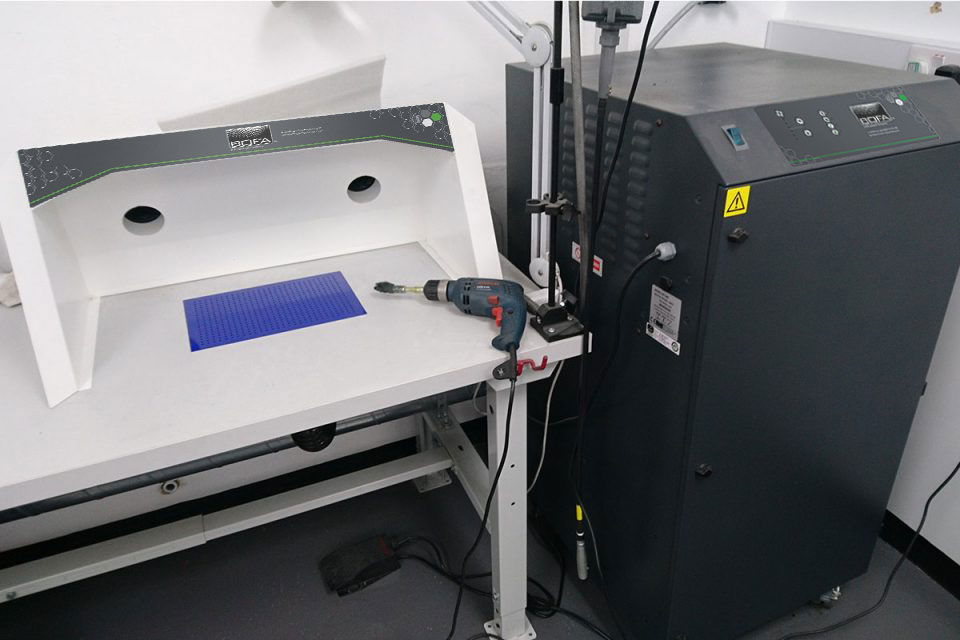

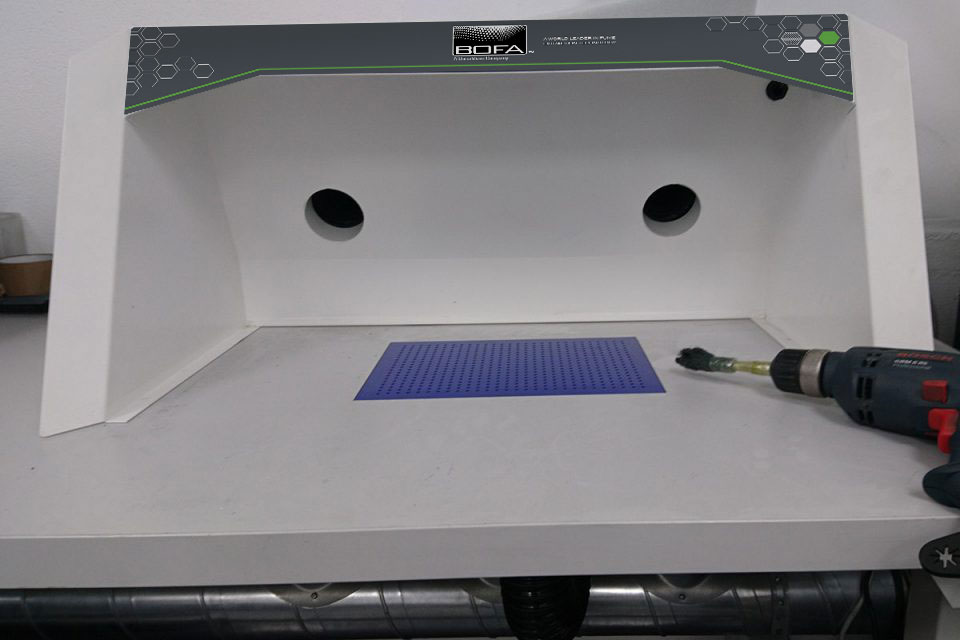

We recommended a modified FumeCAB 600 bench top mounted extraction cabinet which has two rear extraction ports, both of which are connected back to the central BOFA dust collector via a small ductwork system.

Each operator now benefits from:

- A down draft extraction grille which goes through the work surface, allowing extraction direct from the desktop

- General extraction via the bench top mounted enclosure

We adapted our standard extraction cabinet models specifically for the FGP workspace, increasing them in size to meet their operator needs. We supplied one DustPRO 1500 and three DustPRO 1000 extraction units - both models combine a large filter capacity with high airflows and pressure, making them ideal for FGP’s heavy duty applications.

The Result

In a combined team effort, FGP installed and modified their workbenches, and we installed the dust extraction systems. The employees no longer need to wear personal protection equipment, confident that they are working in a safe and clean environment.

In the early months of 2016 FGP identified, with all the progression being made with machining technology that the hand finishing and deburring side of the company was in need of attention. One of the most notable areas that needed improvement was the extraction requirements due to the new type of work being introduced to FGP. With health and safety of the employees being of the utmost importance FGP reached out to BOFA for their expertise and assistance

Between the two companies, a resolution was reached which would fit all applications but meant some modifications and creative thinking would be required. All in all the project was satisfied and completed in a timely manner and has not stopped use since the day of commissioning.

James Bishop, Senior Planning Engineer, FGP Systems Ltd