BOFA finds a solution to regular fire hazard

The Challenge

High power fibre lasers are growing in popularity because of the productivity benefits associated with the faster coding onto metals offered by the technology. They allow more material to be ablated at a faster rate - however, the greater production rates also create higher quantities of flammable and incandescent particles to be generated, which can pose a fire risk.

This was precisely the problem being experienced by one of BOFA’s customers, which operates in the laser coding, marking and engraving industry. Thermal events were happening on a frequent basis and so they turned to BOFA for advice on how best to address the issue.

The Solution

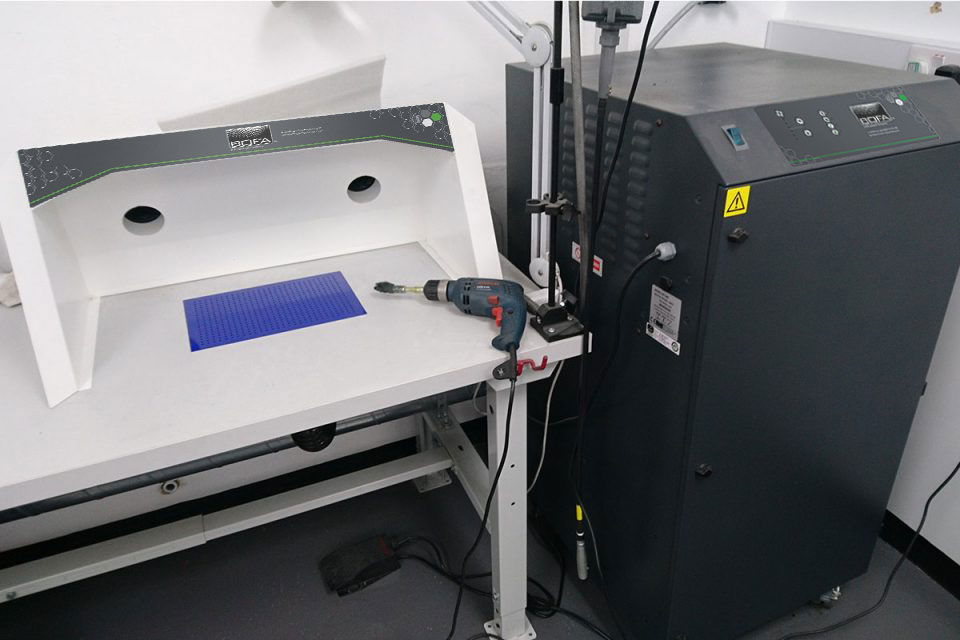

BOFA recommended installing its new self-contained modular Spark Arrestor 2 technology as part of the dust and fume extraction solution. The system works by transporting any hot particles through specially designed impingement plates before depositing them in a removable drop-out chamber. This prevents incandescent particulate created during the fibre laser process from entering the main extraction unit and initiating a fire.

The design of the Spark Arrestor 2 includes a temperature sensor fitted in the outlet port which automatically shuts down the extraction system power in the event of the temperature exceeding a pre-determined level, stopping the air flow to the fire. An audible alarm and warning beacon alerts operators when temperature levels are exceeded, and the extractor shuts down.

The Spark Arrestor 2 is designed so that it can be also used in line with the BOFA FireBOX and FireBOX+ units, which provide additional protection for high temperature fibre laser systems where the process/ materials are more vulnerable to thermal events. These systems also include a self-extinguishing inline pre-filtration and a temperature-linked controller which automatically switches off the extraction system power and activates isolation valves, should the pre-set ambient temperature be exceeded by 10°C. If the temperature rises by another 10°C in the FireBOX, then an integrated fire extinguisher will be activated.

The Spark Arrestor 2 can be used with or without the FireBOX unit.

The Result

BOFA’s client no longer has the worry of regular fires breaking out in its machinery with the self-contained, easy to clean Spark Arrestor 2 installed. The technology has proven to be very effective in capturing high temperature particulate that might otherwise present a fire risk. It has undergone tests in the field and is fully compliant with the machinery directive EN 60204.

The Spark Arrestor 2 is fitted with castors for easy mobility and a lockable door to prevent unauthorised access and is aesthetically designed to complement the style of the BOFA product range.

RNLI

The RNLI is a charity that saves lives at sea. With stations throughout the UK, staff and volunteers are called on every day throughout the year to help people who get into danger in the water.

ALMA STUDIO OF EXCELLENCE

Alma Studio of Dental Excellence is a dental laboratory that was opened in 2015 offering private prosthetic and crown and bridge services. They contacted BOFA regarding new systems to remove the high level of hazardous dust and fumes during their processing.

FGP SYSTEMS LTD

FGP Systems is a precision engineering company offering innovative, high-end solutions to the aerospace industry and other sectors. With a large proportion of work involving the use of hand fettling tools, FGP contact BOFA to help with dust extraction from the production of metal components.