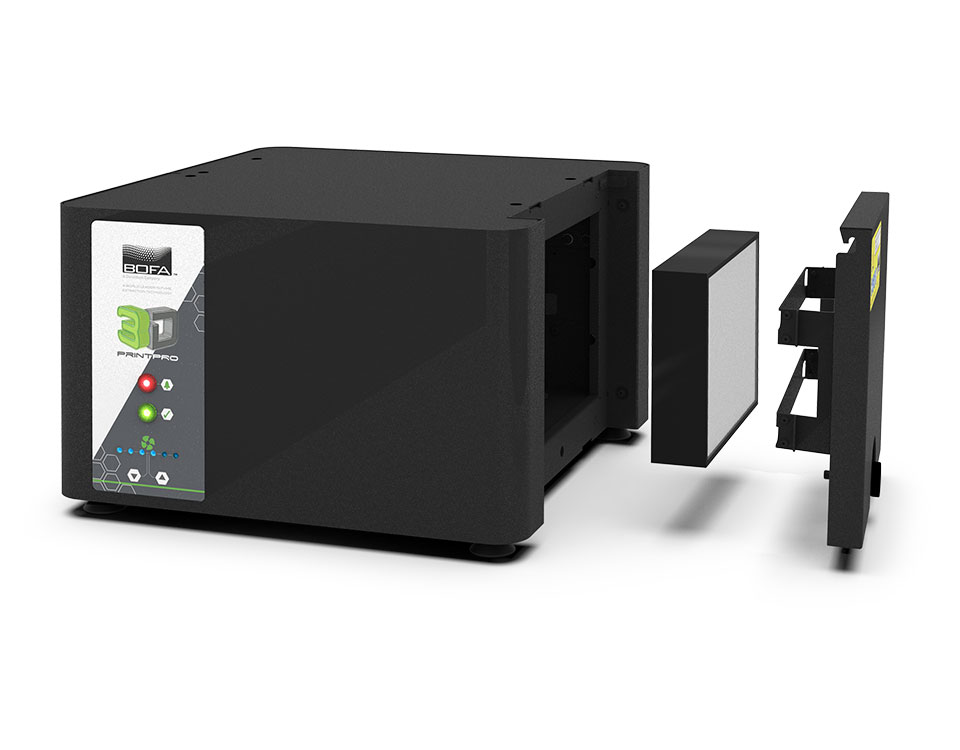

3D PrintPRO HT

3D PrintPRO HT

For enclosed, high-performance 3D printers with up to 100°C chamber air temperature.

The 230V 3D PrintPRO HT provides a premium fume extraction solution for high-performing 3D printers operating with elevated chamber air temperatures. With a modular approach, the design caters for closed-loop continuous operation, open-loop intermittent operation, and the ability to do both with a pairing kit.

Is this the system for you?

Let our knowledgeable team support you in choosing the most appropriate system for your requirements.

We offer a range of accessories for many of our units

Please refer to our accessories page for further information and then get in touch with our experts to define exactly what you need.

Key features of the 3D PrintPRO HT

High temperature

Modular unit

HEPA filter

Mini pleat design HEPA (high efficiency particulate air) filters which are tested and certified to a minimum efficiency of 99.997% at 0.3 microns. They incorporate a series of glue beads between the pleated media. This feature not only guarantees even spacing for full filter coverage between each pleat, but also alleviates the possibility of airflow vibration or collapse.

Advanced carbon filter (ACF) technology

Contaminated air must remain in contact with the carbon bed for a period of time sufficient to ensure that no contaminants or odours are emitted (‘dwell time’). Our filters have been developed to capture all contaminants and odours, eliminating the risk of bypass and/or tunnelling.

Multi voltage sensing (MVS) unit

Automatically senses the local voltage and adjusts accordingly, between 100-230v.

ProTECT service plan

Our ProTECT LEV service plan and compliance certification has been designed to give you the peace of mind that your LEV (Local Exhaust Ventilation) systems are being expertly maintained throughout their working life and you are kept within government guidelines and regulations in the UK.

SureCHECK quality standard

We recognise that quality, health and safety and environmental management are integral to our management. SureCHECK is far more than just written words, it touches every employee and is engrained within the company’s culture and business ethos. It is applied consistently across all our business activities on a world-wide basis.

Technical specification

Ability to filter gas up to 100°C / 212°F

Standard

Low heat loss through insulated construction

Standard

Extended life filters for low cost of ownership

Standard

Low noise level

Standard

Compact construction

Standard

Filter change indicator

Standard

Filter status signals to host machine

Standard

12v DC remote stop/start interface

Standard

UKCA & CE approvals

Standard

Datasheet correct at time of publishing. For specific applications, please contact us for details.